Liquid Leak Detection

Liquid leak detection is the general term for methods and technologies used to detect and control liquid leaks in industrial and commercial facilities. This process is carried out using various devices and techniques and is vital for preventing, detecting, and repairing liquid leaks.

Since liquid leaks pose both environmental and operational risks, accurate and timely detection plays a critical role in the sustainability and safety of businesses. At Ignis Trace, we offer pioneering solutions for liquid leak detection in the Turkish market with the advanced technology products of SOLCO PYROELEC.

What is Liquid Leak Detection?

Liquid leak detection refers to the process of identifying and controlling liquid leaks that occur in industrial facilities, commercial buildings, and various infrastructures. This process involves accurately detecting the source, size, and location of the leak. Liquid leak detection is commonly used to monitor various liquids such as water, chemicals, and petroleum products.

Various methods and devices are utilized in the process of liquid leak detection. Thermal cameras, acoustic listening devices, moisture detectors, and infrared technologies are key components of this process. These devices allow for the quick and accurate identification of the leak's source and path, which accelerates the repair process and prevents environmental and structural damage caused by the leak.

The detection of liquid leaks is of great importance, particularly in preventing environmental and economic damage. At Ignis Trace, we help our customers enhance the safety and efficiency of their facilities by providing liquid leak detection services equipped with the latest technologies.

Water Leak Detection

Water leak detection refers to the process of identifying and controlling unwanted water leaks. This procedure can be applied in a wide range of areas, from building installations to industrial facilities. Water leaks can occur in pipes, connection points, or any water-carrying system, leading to serious structural damage, water waste, and high costs.

Methods used in water leak detection include thermal cameras, acoustic listening devices, and moisture detectors. Thermal cameras detect temperature changes caused by water leaks, while acoustic listening devices pick up the sounds of flowing water. Moisture detectors measure the moisture levels in walls, floors, and other structural elements to pinpoint the location of water leaks.

At Ignis Trace, we use the latest technologies for water leak detection, quickly and effectively identifying potential water leaks in our customers' facilities. By minimizing potential damage, we enhance the safety and operational efficiency of these facilities.

Heating Cable Liquid Leak Detection Devices

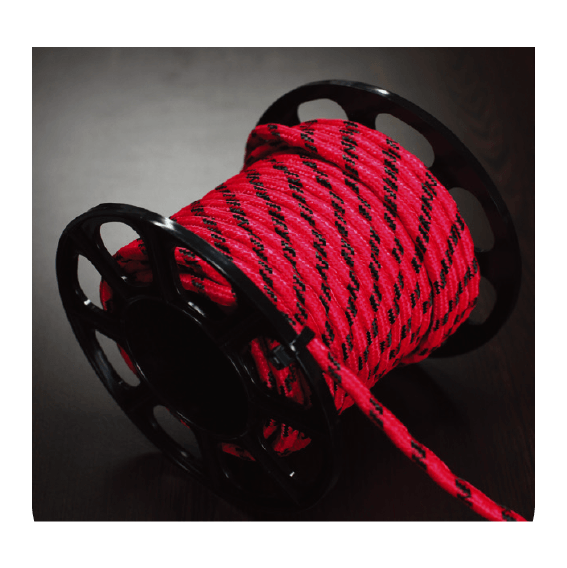

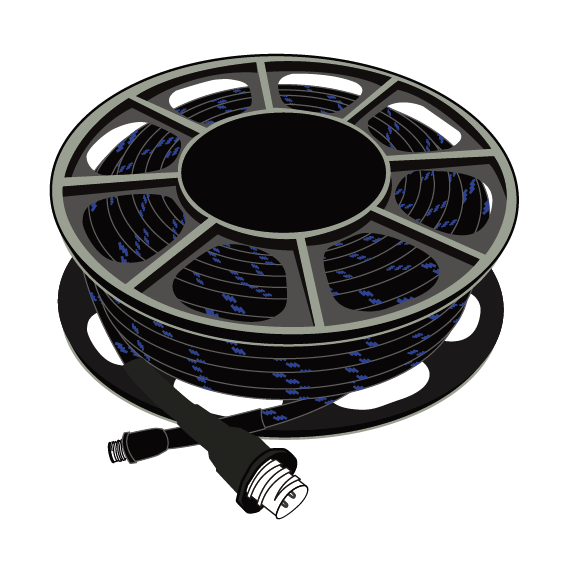

Heating cable liquid leak detection devices are specialized equipment used to detect liquid leaks in heating systems. These devices are designed to ensure the efficiency and safety of heating cables. Liquid leaks in heating cables can lead to energy loss and system failures. Therefore, liquid leak detection devices enable the quick and accurate identification of the leak source, allowing for necessary repair and maintenance actions.

Heating cable liquid leak detection devices typically operate using technologies such as infrared thermometers, acoustic sensors, and moisture detectors. These devices employ different detection methods to identify the location and size of the leak. Infrared thermometers detect temperature changes to locate the leak, while acoustic sensors pick up the sounds of flowing water. Moisture detectors measure the moisture levels in structural elements to determine the leak's location.

How Do Liquid Leak Detection Devices Work?

Liquid leak detection devices use various sensing technologies to detect liquid leaks. These devices typically operate by detecting changes in temperature, moisture, and sound. Infrared thermometers identify temperature differences caused by leaks and use this information to pinpoint the location of the leak. Acoustic sensors detect sounds from water flowing inside pipes and analyze the intensity of these sounds to determine the location and size of the leak. Moisture detectors measure the moisture levels in walls, floors, and other structural elements to locate the leak.

Liquid leak detection devices provide quick and accurate results, enabling the early detection of leaks and timely repairs. This minimizes energy losses and potential structural damage while ensuring the system operates safely and efficiently.

Signs of Liquid Leaks in Heating Cables

Signs of liquid leaks in heating cables typically manifest as anomalies in system performance and environmental conditions. Detecting these signs early is crucial for timely repairs and preventing further damage. Below are some common indicators of liquid leaks in heating cables:

Temperature Drop: Liquid leaks in heating cables can lead to a decrease in heating capacity. This may be evident if the system fails to maintain target temperatures.

Increased Humidity: Leaks can cause an increase in surrounding humidity levels, particularly noticeable in insulated areas.

Increased Energy Consumption: Leaks reduce system efficiency, leading to higher energy consumption. Elevated energy bills could be an indication of a leak.

Visual Signs: Puddles, mold, or moisture stains around the heating cables can indicate the presence of a liquid leak.

Corrosion and Rust: Leaks can cause corrosion and rust on the heating cables and surrounding metal parts.

Degradation of Heating Cables: Leaks can cause damage or deformation to the outer surface of the heating cables, impairing their functionality.

Short Circuit: Liquid leaks in heating cables can cause electrical short circuits, posing a significant safety risk.

Early detection of liquid leak signs in heating cables is critical to ensuring the system operates safely and efficiently.

Features of Liquid Leak Detection Devices

Liquid leak detection devices are designed using advanced technologies to accurately determine the location and size of liquid leaks. These devices have various features that ensure quick and precise detection of leaks. Here are the main features of liquid leak detection devices:

Sensitivity: These devices are designed with high sensitivity to detect even the smallest leaks, enabling early detection and preventing major damages.

Multiple Detection Technologies: These devices utilize a combination of technologies such as thermal imaging, acoustic listening, moisture detection, and infrared sensing. This multi-detection approach helps in accurately identifying the location and size of the leak.

Portability: Liquid leak detection devices are typically designed to be portable and easy to use. Their lightweight and compact structure allow for convenient use in the field.

Real-Time Data Analysis: These devices provide real-time feedback on leak detection, allowing for immediate identification and prompt initiation of repair processes.

Durability: Designed for industrial environments, these devices are built to withstand harsh conditions. They are made with materials that are resistant to water, dust, and impacts, ensuring long-lasting performance.

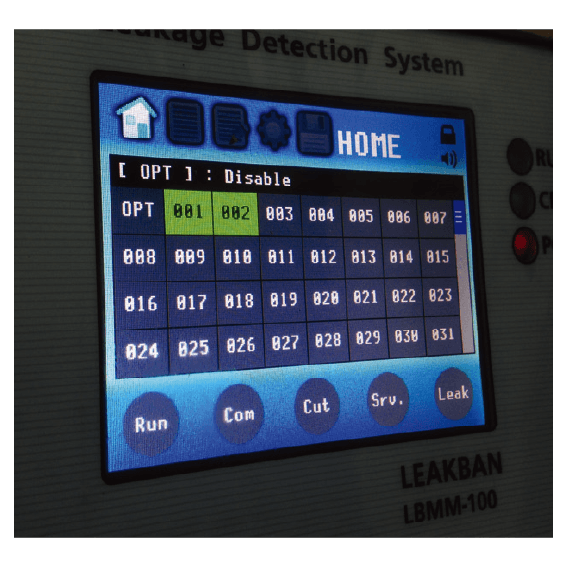

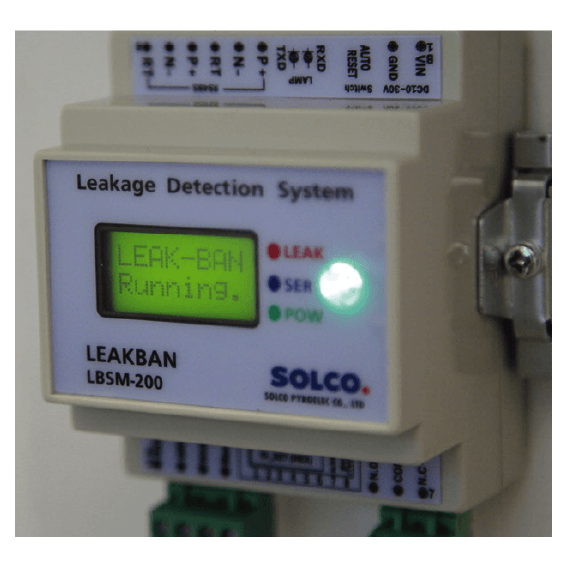

User-Friendly Interface: The devices feature user-friendly interfaces and easy-to-understand displays, enabling operators to quickly and effectively detect leaks. Minimal training is required.

Data Storage and Reporting: Modern liquid leak detection devices can store data on detected leaks and provide detailed reports. These reports facilitate the planning of maintenance and repair processes

Considerations When Choosing a Heat Tracing Liquid Leak Detection System

Selecting the right heat tracing liquid leak detection system is critical for the safety, efficiency, and cost-effectiveness of your operation. Here are the key factors to consider:

System Compatibility: Ensure the chosen leak detection system is compatible with your existing heating cables and infrastructure. Compatibility ensures the system works effectively and the integration process is smooth.

Sensitivity and Accuracy: The system should be capable of detecting even the smallest leaks with high sensitivity. High accuracy ensures the precise identification of the leak’s location and size.

Technological Features: The system should be equipped with advanced technologies. Systems offering multiple detection methods such as thermal imaging, acoustic detection, and moisture sensing provide more effective and reliable results.

Durability and Reliability: Choose a system that can withstand harsh industrial conditions. Systems made from materials resistant to dust, water, and impacts will be more durable and reliable.

Ease of Installation and Maintenance: The system should be easy to install and maintain. User-friendly interfaces and straightforward installation processes reduce operational costs and increase efficiency.

Real-Time Monitoring and Alerts: The system should provide real-time monitoring and immediate alerts for potential leaks. This feature allows for quick intervention to minimize damage.

Data Storage and Reporting Capability: The system should be capable of storing data on detected leaks and providing detailed reports. These reports facilitate the planning of maintenance and repair processes.

Cost and Economy: The cost of the system should align with your budget. However, remember that the cheapest option is not always the best. Choosing a high-quality system that offers long-term cost-effectiveness is more important.

Support and Service: Consider the support and service provided by the manufacturer or supplier. Good technical support and a robust service network ensure quick resolution of any issues.

By taking these factors into account, you can select a heat tracing liquid leak detection system that best meets your operational needs and ensures long-term reliability and efficiency.

Frequently Asked Questions About Liquid Leak Detection

Türkçe

Türkçe