Temperature Measurement

Temperature measurement is the process of accurately and reliably determining the temperature in industrial processes and various applications. Accurate temperature measurement is critical to ensuring the efficiency and safety of processes.

What is Temperature Measurement?

Temperature measurement refers to the process of determining the temperature of an environment, substance, or surface. This measurement is carried out using various devices such as temperature sensors, thermometers, or thermocouples. In industrial applications, temperature measurement is vital for the control and safety of processes. Accurate temperature measurement increases energy efficiency, maintains product quality, and ensures safe working conditions.

Temperature measurement is widely used not only in industrial facilities but also in laboratories, medical devices, food production, and even daily household uses. Temperature measurement devices are known for their precision and reliability and must be regularly calibrated to ensure accurate measurements. These devices are designed to be unaffected by environmental conditions during measurement and provide users with accurate and precise information.

Heating Cable Temperature Measurement Devices

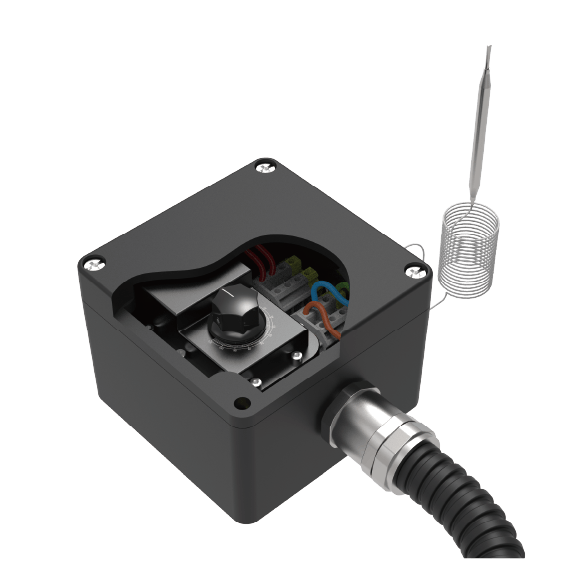

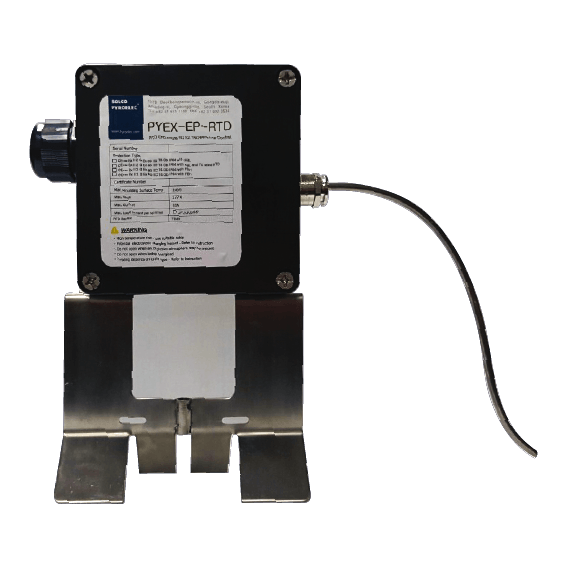

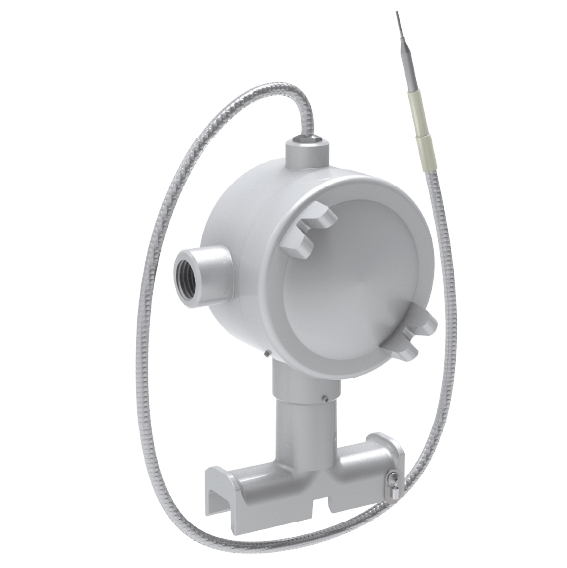

Heating cable temperature measurement devices are specialized devices used to monitor and control the performance of heating cable systems. These devices monitor the temperature along the cable, ensuring the system operates correctly and efficiently. Heating cable temperature measurement devices are typically used in industrial facilities, pipelines, storage tanks, and various engineering applications.

These devices consist of temperature sensors, transmitters, and controllers. Temperature sensors are placed at specific points along the cable and collect temperature data. This data is transmitted to the controllers via transmitters. The controllers analyze the temperature data and regulate the heating cable's temperature, ensuring optimal performance. Heating cable temperature measurement devices save energy and prevent the system from overheating or cooling down, thus providing long-lasting and reliable operation.

Concrete Temperature Measurement Device

A concrete temperature measurement device is used to monitor temperature changes during the pouring and curing process of concrete. These devices measure the internal and external temperatures of concrete, helping to ensure optimal curing conditions. Concrete temperature measurement devices are widely used in large construction projects, bridges, tunnels, and high-rise buildings.

Controlling the temperature of concrete is critical for ensuring structural integrity and durability. These devices ensure the concrete cures uniformly and prevents cracking. Additionally, concrete temperature measurement devices accelerate the construction process, contributing to the timely completion of projects.

What are Heating Cable Temperature Measurement Devices?

Heating cable temperature measurement devices consist of various devices used to ensure the efficient and safe operation of heating cable systems. These devices measure temperatures at different points in the system, optimize the performance of the heating cable, and save energy. Heating cable temperature measurement devices include temperature sensors, transmitters, and controllers.

The temperature measurement devices used in heating cable systems are designed and manufactured in accordance with industrial standards. These devices operate with high precision, increasing the reliability and efficiency of the system. Additionally, these measurement devices prevent the system from overheating, providing long-lasting and safe use. Heating cable temperature measurement devices are widely used in various applications, especially in pipelines, tanks, and industrial facilities.

Temperature Sensors

Temperature sensors are devices used in heating cable systems designed to collect temperature data. These sensors are placed at different points along the heating cable and continuously measure the ambient temperature. The collected data is used to maintain the system's temperature control and ensure optimal performance. Temperature sensors are known for their high precision and reliability and are widely used in various industrial applications.

Transmitter

Transmitters are components that transmit data from temperature sensors to control devices. In heating cable systems, temperature values measured by temperature sensors are transferred to the central control unit via transmitters. These transmitters typically operate using wireless or wired connection methods, ensuring the data is transmitted quickly and accurately.

Transmitters guarantee the continuous transmission of temperature data, allowing the system to be monitored in real time. This ensures the efficient and safe operation of the heating cable system, contributing to energy savings and reducing operational costs.

Controller

The controller can be considered the heart of heating cable systems. This device analyzes data from temperature sensors and transmitters, controlling and regulating the system's temperature level. The controller automatically turns the system on or off according to pre-determined temperature settings, maintaining the desired temperature level.

Controllers are known for their user-friendly interfaces and programmable features. These devices operate automatically without manual intervention, increasing operational efficiency and saving energy. Additionally, controllers prevent the system from overheating, providing safe and long-lasting operation.

How is Temperature Measurement Performed in Heating Cables?

Temperature measurement in heating cables is carried out using temperature sensors placed at specific points along the cable. These sensors continuously monitor the temperatures of the cable and the surrounding environment, transmitting the measured data to the transmitters. The transmitters transfer the temperature data to a central control unit. The control unit analyzes this data, ensuring the heating cable operates at an optimal temperature.

During temperature measurement, control mechanisms are activated to prevent the cable from overheating or cooling down. The controller automatically regulates the system according to pre-determined temperature limits. This ensures the system operates efficiently and safely. Additionally, regular maintenance and calibration enhance the accuracy and reliability of temperature measurement devices.

Advantages of Heat Tracing Temperature Measurement

Heat tracing temperature measurement offers a range of significant advantages in industrial facilities and various applications. Firstly, these systems ensure operational continuity by preventing the freezing of liquids in pipelines and tanks. Heat tracing temperature measurement systems increase energy efficiency and reduce energy costs through precise temperature control.

Secondly, these systems extend the life of equipment and reduce maintenance costs by preventing overheating. Heat tracing temperature measurement devices detect and prevent potential failures early by continuously monitoring and controlling the temperature. This increases operational safety and prevents workplace accidents. Lastly, these systems can be adapted to different industrial processes and used in various applications.

What to Consider When Selecting Heating Cable Temperature Measurement Devices

There are several important factors to consider when selecting temperature measurement devices for heating cables. Firstly, accuracy and precision are crucial. The selected device must be able to measure with high accuracy and precision to ensure the system operates efficiently and reliably. Secondly, compatibility should be considered. The devices must be compatible with existing heating cable systems to facilitate the integration process and prevent additional costs.

Another important factor is durability and longevity. Since heating cable systems typically operate under harsh environmental conditions, the devices must be durable and long-lasting. Additionally, ease of maintenance and calibration options should be considered. Devices that are easy to maintain and calibrate require less cost and labor in the long term. Finally, the price-performance balance should be considered, and the most cost-effective and high-performance devices should be preferred.

Türkçe

Türkçe