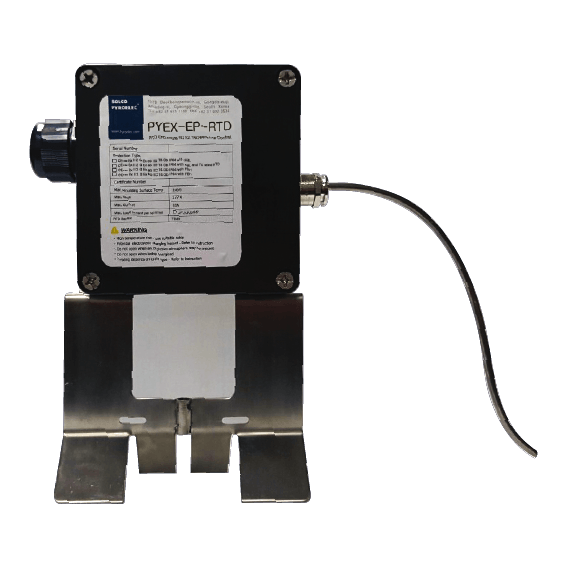

RTD Thermocouple Temperature Sensor

Mineral Insulated RTD sensor / Thermocouple

- Temperature sensor for high temperature range

- MI materials and AISI 316L

- RTD(pt100) or thermocouple

- Ex certified heat trace temperature sensor

Thermocouple (Temperature Sensor)

A thermocouple is a highly reliable and widely used temperature sensor that measures temperature through the electrical voltage generated by two different metal wires joined at one end. This simple yet effective device is essential in various industries, from manufacturing and automotive to research laboratories and HVAC systems. With different thermocouple types available, including the popular type K thermocouple and type J thermocouple, users can select the ideal solution based on temperature range, sensitivity, and application needs.

Thanks to its robust construction, fast response time, and broad temperature range, the thermocouple sensor remains a preferred choice in both harsh and controlled environments. From understanding the thermocouple working principle to analyzing thermocouple wiring diagram, selection and proper usage are key to maximizing measurement accuracy. In this guide, we’ll explore types, applications, prices, and how to troubleshoot thermocouple failure, while also comparing with technologies like RTD thermocouple.

What is a Thermocouple?

A thermocouple is a type of temperature measurement sensor made from two dissimilar metal wires joined at one end. When the junction of these metals experiences a temperature change, a small voltage is generated, which corresponds to the measured temperature. This phenomenon, based on the Seebeck effect, is what makes thermocouples simple yet powerful tools for temperature monitoring. They are widely used across industries due to their rugged design and wide temperature range capabilities.

Because of their adaptability, thermocouples come in various configurations and materials to suit different applications. From industrial furnaces to home appliances, a thermocouple can be found in any setting where accurate thermal readings are needed. Its reliability, cost-effectiveness, and easy integration into automation systems make it one of the most commonly used temperature sensing devices worldwide.

What Does a Thermocouple Do?

A thermocouple functions as a sensor that converts temperature into an electrical signal. This signal can then be interpreted by controllers or readout devices to monitor or regulate heating and cooling processes. It plays a crucial role in industrial automation, scientific experiments, and safety systems, enabling real-time temperature tracking in both low and high-temperature environments.

Thermocouple Types

Thermocouple types vary based on the metals used in their construction, which determine their temperature range, durability, and accuracy. The most common types include type K thermocouple and type J thermocouple, though there are several others like Type T, E, N, R, S, and B. Each type serves different application needs, from cryogenic environments to extreme industrial heat. Selecting the right type ensures optimal performance, longevity, and safety.

For instance, type K thermocouples are popular for their broad temperature range and resistance to oxidation, making them suitable for general industrial applications. Type J thermocouples, on the other hand, offer excellent sensitivity at lower temperatures. Understanding different thermocouple types allows engineers and technicians to match the sensor with the operating environment for accurate and efficient temperature measurement.

K Type Thermocouple

The type K thermocouple is one of the most commonly used thermocouples due to its wide temperature range (-200°C to 1260°C) and excellent durability. Made from nickel-chromium and nickel-aluminum alloys, it offers strong resistance to oxidation and is ideal for use in furnaces, engines, and heat treating applications. It’s a reliable, cost-effective solution for general-purpose temperature sensing.

J Type Thermocouple

The type J thermocouple is made from iron and constantan, offering a temperature range of -40°C to 750°C. It provides excellent sensitivity at lower temperatures and is widely used in plastics, food processing, and HVAC systems. However, because the iron element is prone to oxidation, it is best suited for clean, dry environments where corrosion risk is minimal.

Thermocouple Working System

The thermocouple working principle is based on the Seebeck effect, which states that when two dissimilar metals are joined at one end and exposed to a temperature difference, they generate a measurable voltage. This voltage is directly proportional to the temperature difference between the measurement (hot) junction and the reference (cold) junction. This simple yet effective mechanism is what allows thermocouples to function without an external power source.

Thanks to this principle, thermocouples can detect a wide range of temperatures quickly and accurately. The output signal is sent through a thermocouple cable to a control system or digital display for real-time monitoring. This robust and fast response system makes thermocouples ideal for industrial processes, laboratory experiments, and thermal management in electronics or automotive systems

How to Calibrate Thermocouple?

Calibrating a thermocouple involves comparing its readings to those of a precise reference device, such as a thermocouple thermometer or a calibration bath. The sensor is exposed to known temperatures, and any deviations are adjusted digitally or manually. Regular calibration ensures accuracy, especially in critical environments like laboratories or manufacturing lines where temperature precision is vital.

How to Connect a Thermocouple?

A proper thermocouple connection is essential for accurate temperature readings. The positive and negative wires must be connected to the correct terminals on the measuring device, ensuring polarity is maintained. Special thermocouple extension wires or connectors are often used to prevent signal loss. A secure and stable connection helps eliminate electrical noise and improves long-term measurement reliability.

Thermocouple Temperature Sensor Prices

Thermocouple Temperature Sensor prices vary depending on factors such as type, temperature range, wire material, sheath quality, and the length of the thermocouple cable. Basic models like type J thermocouple or type K thermocouple are usually more affordable, making them ideal for standard industrial and lab environments. However, high-precision sensors with protective coatings or customized configurations may cost significantly more.

When purchasing a thermocouple, it’s also important to consider additional components such as thermocouple cable, connectors, and compatible controllers, which can affect the overall cost. Investing in a high-quality sensor may have a higher upfront cost but offers better durability, reduced thermocouple failure risk, and long-term measurement accuracy. Always match the sensor's specs with your application's requirements to ensure value and performance.

Benefits of Thermocouple Temperature Sensor

A thermocouple sensor offers several advantages that make it a popular choice for industrial, commercial, and scientific temperature measurement. One of its greatest strengths is the wide temperature range it can cover—from cryogenic levels to extreme heat. It’s also known for its fast response time, allowing near-instant feedback for real-time system monitoring. Thermocouples are compact, durable, and resistant to harsh environments, which makes them suitable for high-vibration or corrosive settings.

Another key benefit is their compatibility with a wide range of equipment. Most data loggers, controllers, and automation systems support thermocouples, making integration seamless. Additionally, their simple design and low cost provide an excellent balance between performance and budget, making thermocouple sensor solutions ideal for both small-scale projects and large industrial operations.

Things to Consider in Thermocouple Temperature Sensor Selection

When selecting a thermocouple, the first step is understanding the application environment and temperature range. Different thermocouple uses demand different materials and construction types—what works for a laboratory setting may not be suitable for a foundry or kiln. Consider factors like response time, chemical exposure, installation limitations, and vibration when choosing the right sensor type. Also, ensure compatibility with the data acquisition or control system you’ll be using.

In some cases, users may need to decide between a traditional thermocouple and a rtd thermocouple, which offers higher accuracy at lower temperature ranges. While RTDs are more precise, thermocouples are more rugged and better suited for extreme heat and fast-changing environments. The right decision comes down to balancing accuracy, durability, and budget for your specific application.

Temperature sensor:

W-M-303-@/®-©/FDF-4-A-Ex : Pt100T-M-303-@/®-©FDS-Z-1-Ex : Thermocouple K or N typeMax. measuring current : 10mA

Temperature range : -60°C ...+450°C Temporary +550 °CDiameter of sensor probe : 3mm, 6mm, 8mm

Tinned copper connection Wires : 0.22mm?

Max. service temperature (connection to MI cable) : +130°CMax. service temperature (end sleeve) : +105°C

Türkçe

Türkçe