Connection Kits

Connection kits play a vital role in industrial heating systems. These kits are used to ensure the safe and efficient operation of heating cables and typically consist of various components. Electrical connection kits, termination kits, T-kits, Ex-proof connection boxes, junction boxes, and similar products include various components such as labeling tags.

These components are of critical importance in the installation and maintenance of heating cables. At Ignis Trace, we are a leader in industrial heat tracing solutions, offering high-quality and reliable connection kits. Let's now delve into what connection kits are and explore various types in more detail.

What is a Connection Kit?

A connection kit is defined as a set containing all the components necessary for the safe and efficient operation of heating cable systems. These kits ensure the proper connection and protection of heating cables during installation and afterwards.

Connection kits typically consist of electrical connection kits, termination kits, T-kits, Ex-proof connection boxes, junction boxes, and similar products, as well as labeling tags. These components are assembled to ensure the safe and effective operation of heating cables.

Connection kits are widely used in various industrial applications, especially in heat tracing systems.

Heat Tracing Connection Kits

Heat tracing connection kits are components designed to ensure the safe and efficient operation of heating cables used in heat tracing systems. These kits ensure proper connection, protection, and termination of heating cables when needed.

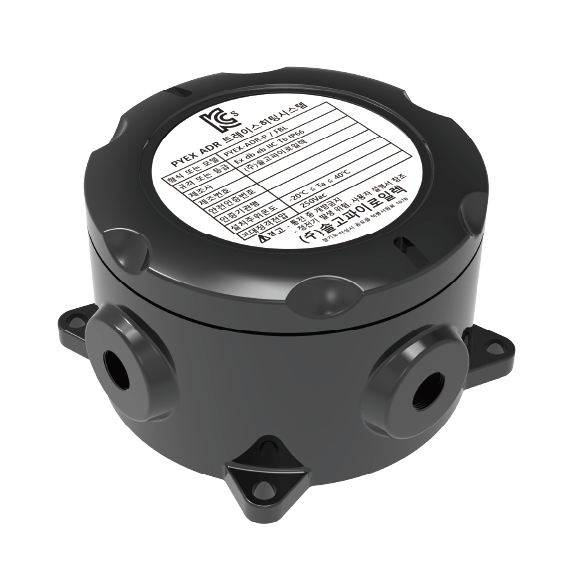

Heat tracing connection kits are critically important for safety and efficiency, especially in high-risk industrial areas. Components such as electrical connection kits, termination kits, T-kits, and Ex-proof connection boxes are used to enhance the safety and optimize the performance of these systems. Additionally, auxiliary components like labeling tags facilitate easy identification of cables and connection points.

Types of Heating Cable Connection Kits

Heating cable connection kits are divided into various types according to different applications and needs. These kits contain components necessary for the safe and efficient operation of heating cables. Types of heating cable connection kits include termination boxes, connection elements, insulation materials, and other accessories.

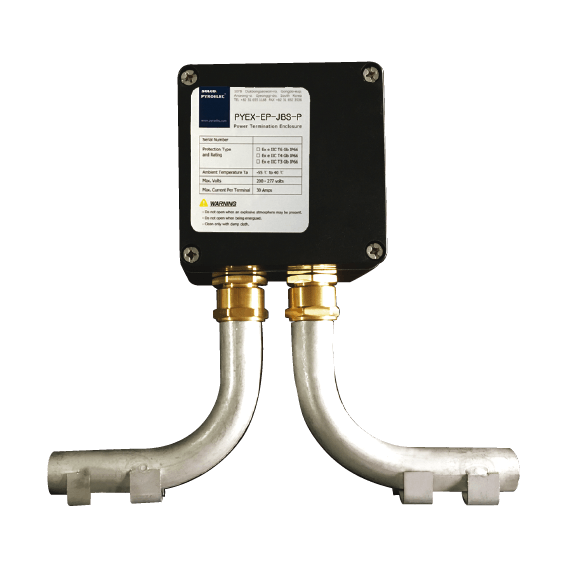

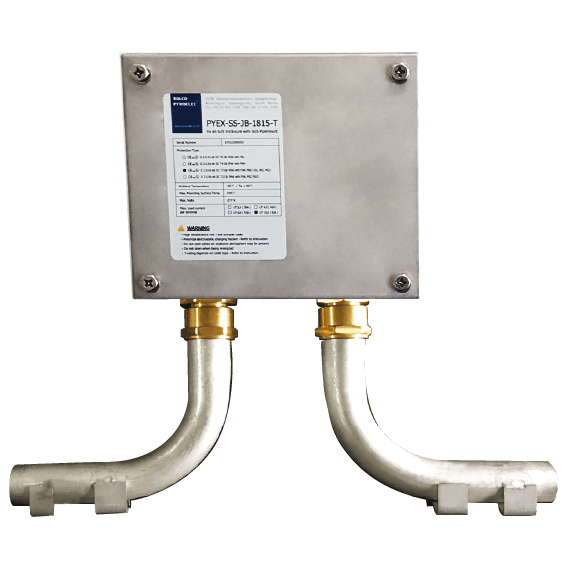

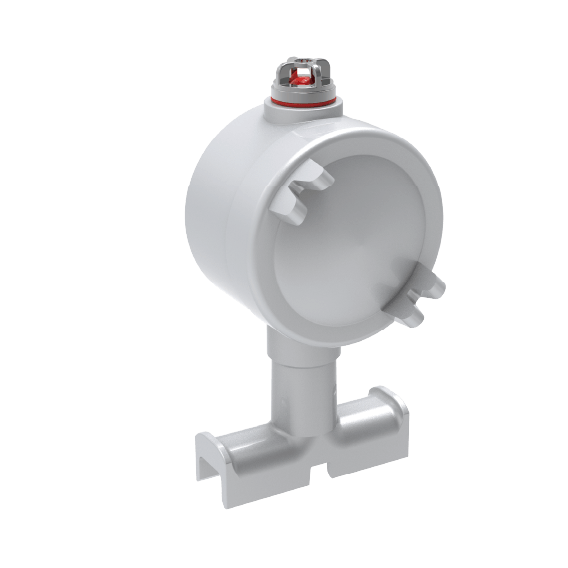

Termination Boxes

Termination boxes ensure the termination and safe connection of heating cables. These boxes are designed to protect electrical connections and are typically Ex-proof, suitable for use in areas with explosion risks.

Connection Elements

Connection elements are used to join different sections of heating cables and facilitate processes such as cutting, connecting, and rerouting cables.

Insulation Materials

Insulation materials protect heating cables from environmental conditions, increase cable efficiency, and prevent energy loss.

Other Accessories

Other accessories support the installation and maintenance of heating cable systems, including mounting brackets, clamps, and labeling tags, among others. These components enhance the overall performance and safety of the system.

What are the Advantages of Heating Cable Connection Kits?

Heating cable connection kits offer numerous advantages for the safety and efficiency of industrial heating systems. These advantages ensure that systems operate more effectively and securely, reducing operating costs and increasing operational efficiency.

Firstly, connection kits allow for quicker and safer installation and termination of heating cables. This reduces labor costs and shortens installation time. Additionally, these kits help protect the cables from environmental factors, ensuring the system's longevity.

Secondly, connection kits enhance electrical safety by ensuring that heating cables are connected correctly and securely. This minimizes fire risks and other safety issues. Moreover, insulation materials and other accessories improve energy efficiency by preventing heat loss, thus reducing energy costs.

Lastly, these kits can be used in various industrial applications, making them a versatile and flexible solution. Especially in high-risk areas, explosion-proof (Exproof) junction boxes and other specialized components enhance the safety and durability of systems.

What Are the Types of Heating Cable Connection Kits?

Heating cable connection kits vary according to different industrial needs and applications. Each type of connection kit serves a specific purpose and ensures the safe and efficient operation of heating cables. Here are the main types of heating cable connection kits:

Termination Boxes

Termination boxes are used to safely terminate the ends of heating cables. These boxes protect electrical connections and are resistant to external factors. Explosion-proof termination boxes are particularly preferred in areas with explosion risks.

Connection Elements

Connection elements are used to connect different sections of heating cables and ensure the cables are placed in an orderly manner. These elements facilitate cable installation and provide a secure connection.

Insulation Materials

Insulation materials protect heating cables from environmental conditions. These materials increase the energy efficiency of the cables and enhance their durability against external factors. Insulation materials minimize heat loss and save energy.

Other Accessories

Other accessories include various components that support the installation and maintenance of heating cable systems. These accessories include mounting brackets, clamps, marking tags, and junction boxes. These components improve the overall performance and safety of the system.

How to Choose Heat Tracing Connection Kits?

Choosing heat tracing connection kits is crucial for the efficient and safe operation of heating systems. Selecting the right connection kit maximizes system performance while minimizing safety risks. Here are some important factors to consider when choosing heat tracing connection kits:

Firstly, the application area and environmental conditions should be considered. Connection kits should be suitable for the temperature, humidity, chemical exposure, and explosion risk of the environment where they will be used. For example, explosion-proof junction boxes should be preferred in areas with explosion risks.

Secondly, the type and characteristics of the heating cable should be taken into account. The type, power, length, and other technical specifications of the heating cable play an important role in determining the appropriate connection kit. Termination boxes, termination kits, and other connection elements should be suitable for the technical specifications of the cable.

Thirdly, ease of installation and maintenance is an important factor. Connection kits should offer quick and easy installation while also facilitating maintenance and repair processes. This reduces labor costs and extends the system's lifespan.

Lastly, compliance with standards and certifications should be considered. Connection kits should comply with national and international safety and quality standards. This ensures that the system operates safely and meets legal requirements.

Türkçe

Türkçe