LEAKBAN LDS

SOLCO Leakban-LDS Fluid Leak Detection System

Power plant and sub-station : water and various chemical detection around power generation plants, data centres, central command units

Digital media centre : water detection including floor surfaces, subfloors and equipment locations

Semi-conductor, battery, display panel (LCD/LED) factory : water, acid and base leakage detection around pipes, storage tanks, and trenches such as sulphuric acid, sulphurous acid, nitric acid, PAC and sodium hydroxide etc.

Army bases : Oil and chemical leak detection including pipes and storage tanks SOLCO intrinsically safe leak detection system is approved for installation in ordinary and hazardous areas when used with LBSC-1000 or LBSC-7000 sensing cable with safety barrier being stated in the Ex certificates. Protection Ex ia IC T4 Ga Certificate No.

BASEEFA 15Y0074, IECEx BAS15.0064X. You can download our heat trace product catalogue below.

Features of LEAKBAN System

Conforms with relevant EMI/EMC and Electrical Safety requirements

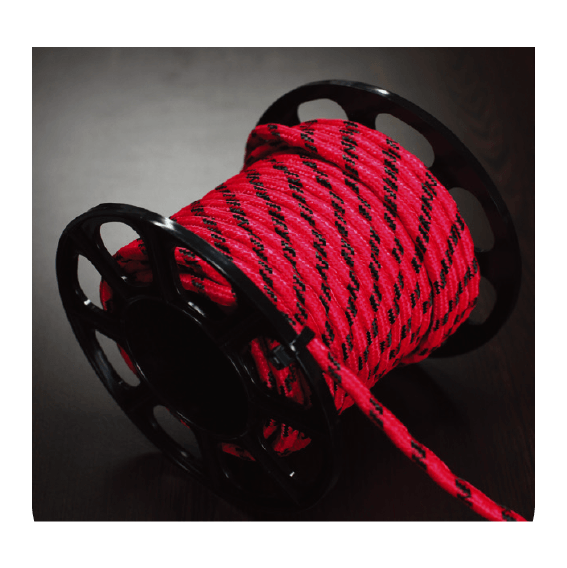

Sensing cable can be connected up to 1km

Fast response (default 8 seconds)

Leak point positioning within ± 1m / 1,000m

Sensing wires sit in deep grooves making it fault-free

Durable and flexible / Reusable

Chemical and abrasion resistance

Standard supply lengths: 3m, 7.5m, and 15m

Network System

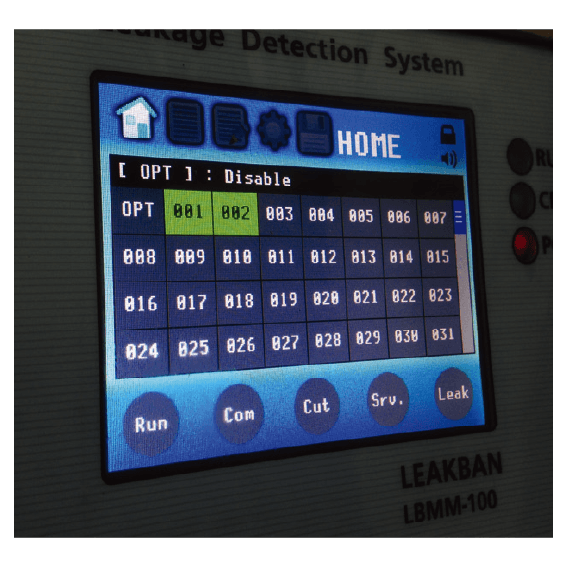

EAKBAN LBMM-100, the main display module, is connected with

LBSM, the Submodule, via RS485 and monitors the status of all

the linked submodules and sensing cables. When a leakage is

detected, it automatically triggers an auditory and visual alarm for

recognition and alert from a distance. Max. 32 submodules can be

linked with LBMM-100 via RS485, and each submodule can

accommodate up to 500m of sensing cable at maximum.

Stand-Alone System

LBMM-100, main display module can be directly connected with a

leak sensing cable without a LBSM. It can accommodate up to

1,000m of sensing cable at max. On the other hand, LBSM-200 or

LBSM-300, submodules can be used without the LBMM. If

necessary, it can be connected with a Windows PC via the

RC-MBT unit for monitoring the status of leak sensing cables and

for positioning the point where the leakag

Türkçe

Türkçe