Temperature control is one of the most crucial elements in modern industrial production. Whether it's maintaining the flow of raw materials, initiating chemical reactions, or ensuring final product quality, heat plays an essential role in virtually every industrial process. This is where process heating becomes indispensable. A process heating solution refers to any system designed to supply controlled heat energy directly to a production process. From food manufacturing and petrochemical refining to pharmaceuticals and energy generation, these systems ensure the safe, efficient, and consistent operation of temperature-sensitive procedures. Without reliable heating infrastructure, many critical operations would suffer from inefficiency, increased costs, and potentially hazardous working conditions.

At its core, a process heating system comprises heating elements, control units, insulation materials, and monitoring components, all integrated to maintain optimal thermal conditions. These systems are designed to suit specific applications, allowing for tailored temperature ranges, distribution methods, and automation levels. The ability to maintain thermal stability throughout a process is vital for productivity, safety, and energy efficiency. Industrial process heating systems go beyond basic heat delivery—they are engineered to provide sustainability, precision, and scalability in complex environments. As industries strive for greater energy efficiency and environmental responsibility, modern process heating systems have become smarter, safer, and more adaptable than ever before.

What is a Process Heating System?

A process heating system is a specialized solution used to deliver controlled heat to industrial processes that require precise temperature management. These systems are essential in operations where heating is critical to facilitate chemical reactions, ensure the flow of viscous materials, maintain hygiene, or achieve desired physical changes in materials. They are commonly used in sectors such as food processing, petrochemical manufacturing, pharmaceuticals, energy production, and more. Process heating can involve conduction, convection, or radiation methods, depending on the specific requirements of the production environment. Unlike conventional heating solutions, process heating systems are designed to integrate seamlessly with automation and control technologies, enabling real-time adjustments and performance monitoring. This makes them ideal for modern industrial facilities seeking consistency, energy efficiency, and safety. Their implementation helps reduce heat loss, minimize energy waste, and improve overall production reliability. Additionally, these systems are highly customizable, which allows them to serve a wide range of temperature ranges and environmental conditions. They are often built to meet industry standards and regulations, ensuring safe and compliant operation.

At the most basic level, process heating systems consist of heating sources such as electric heating cables, heaters, or thermal fluids, along with sensors, insulation materials, and advanced control units. The heating components are typically installed around or within process equipment like pipelines, tanks, or processing vessels to maintain constant thermal conditions. As industries evolve, the demand for flexible and efficient thermal systems has grown, pushing manufacturers to develop process heating technologies that are modular, scalable, and easy to maintain. Today, many systems are equipped with IoT-based monitoring tools and programmable logic controllers (PLCs) to further enhance control and diagnostics. These capabilities allow operators to not only monitor system performance but also predict and prevent failures before they occur. Furthermore, by implementing well-designed process heating solutions, companies can reduce energy costs, meet environmental targets, and maintain product quality—all while enhancing operational safety. This adaptability and range of benefits make process heating systems an essential component in modern industrial infrastructure.

How Do Process Heating Systems Work?

Process heating systems function by transferring thermal energy directly into industrial equipment or materials to maintain or elevate temperature during a specific stage of production. This is achieved through various technologies such as electric heating elements, steam systems, hot oil circuits, or infrared heat sources. The choice of heating method depends on the application requirements—such as temperature range, heat-up speed, environmental factors, and safety considerations. A common configuration involves heating cables or elements installed along pipelines or tank surfaces, supported by sensors and insulation materials to ensure uniform heat distribution and minimal energy loss. Once installed, the heating system is activated and controlled by a centralized unit that regulates energy output based on temperature feedback from the system’s sensors. The result is precise thermal management that ensures consistent performance across the production process.

The true efficiency of a process heating system lies in its ability to automatically adapt to real-time changes. Advanced systems often include programmable logic controllers (PLCs) or industrial automation software that continuously monitor performance, detect temperature fluctuations, and make instant adjustments to avoid overheating or underheating. These systems also typically include built-in safety mechanisms to shut down components in the event of system faults, protecting both equipment and personnel. In high-risk industries like petrochemicals or pharmaceuticals, such features are not just convenient—they are mandatory. Additionally, process heating systems may be integrated into broader building or facility management systems, enabling centralized oversight of thermal conditions across multiple zones or production lines. Over time, the system's data logs can be analyzed to optimize energy usage, improve throughput, and reduce maintenance needs. In short, process heating systems work by delivering reliable, responsive, and highly controllable heat exactly where—and when—it’s needed.

Key Components of Process Heating Systems

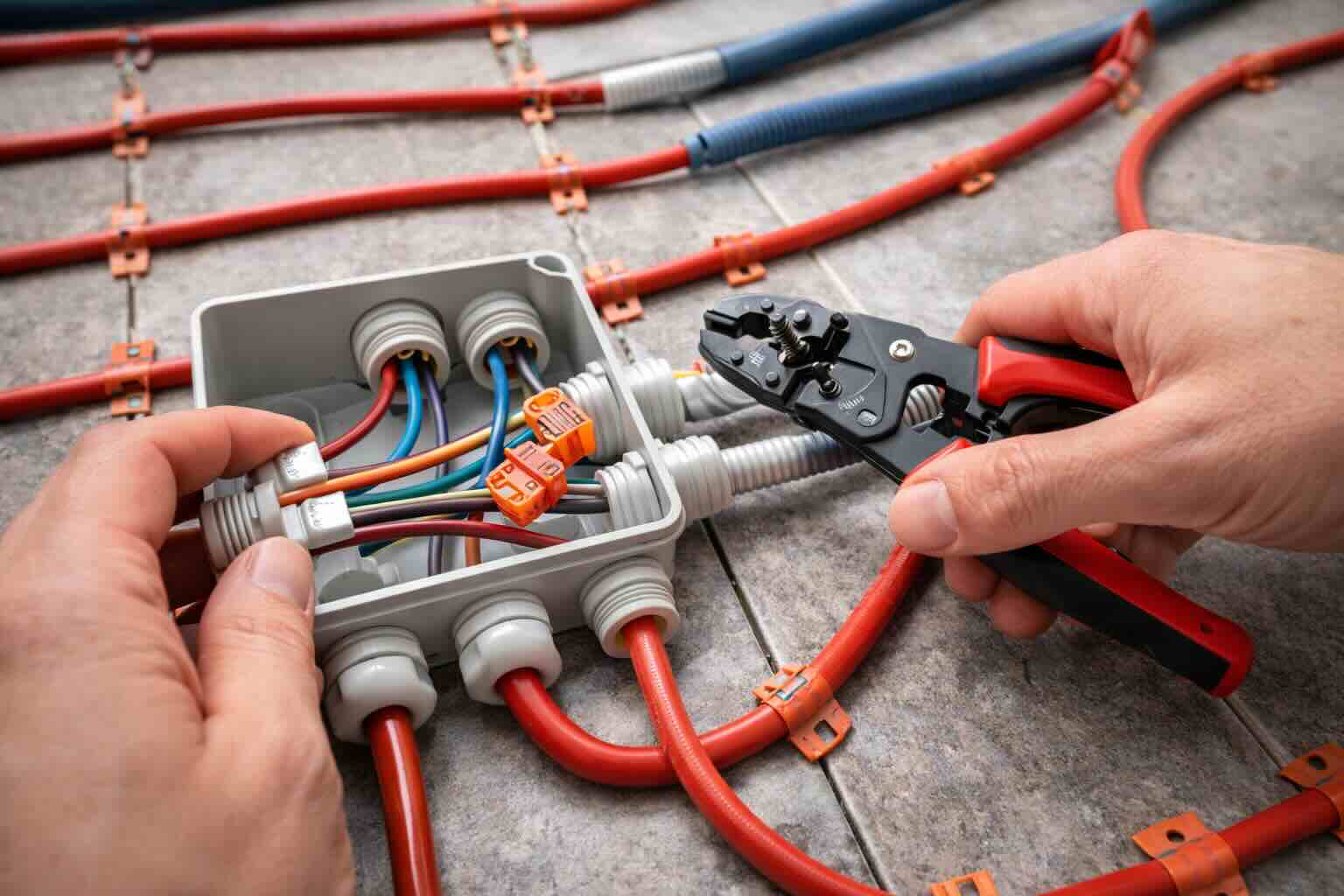

A well-designed process heating system is made up of multiple interconnected components that work together to deliver safe, efficient, and reliable heat. While the heating element is at the heart of the system, it cannot function effectively without proper insulation, control systems, and monitoring tools. These components ensure that the heat is applied exactly where it's needed and maintained at consistent levels throughout the production process. Heating cables, for example, are often installed along pipelines or storage tanks to prevent temperature loss during transport or storage. These are supported by high-performance insulation materials that reduce thermal losses and energy consumption. Control units play a vital role in continuously adjusting output based on real-time feedback, maintaining process integrity and avoiding overheating or underheating. Each element must be selected carefully based on the specific process requirements, environmental factors, and safety regulations. Integration between these components is essential to achieving optimum system performance. When properly configured, a process heating system enhances productivity, reduces downtime, and extends the life of equipment. Furthermore, modular component design allows for future expansion or system upgrades without full replacement. In modern facilities, these components often communicate through digital protocols, ensuring smart, responsive heat control.

Another key benefit of having a component-based approach to process heating system design is adaptability. Industries vary significantly in their operational needs, temperature thresholds, and compliance standards. By having customizable components—such as heating cables with varying watt densities, or control panels with advanced automation features—engineers can tailor systems for each unique application. Additionally, this flexibility allows for simplified maintenance and faster troubleshooting. For example, if a heating zone fails, individual components can be replaced or recalibrated without affecting the entire system. Advances in sensor technology have also made it possible to track thermal performance in real time, enabling predictive maintenance and reduced downtime. Most modern systems include data logging and alarm capabilities, helping operators react quickly to anomalies. High-quality insulation prevents energy waste, while intelligent control systems ensure safe operation even in extreme environments. These components are not just supportive—they are essential to maintaining process efficiency, safety, and compliance. Let’s now take a closer look at each of the three primary components in more detail.

Heating cables

Heating cables are one of the most fundamental components of any process heating system. They are typically used to maintain or raise temperatures in pipes, tanks, or vessels by applying heat directly to the surface. Depending on the application, heating cables can be constant wattage, self-regulating, or mineral insulated. Self-regulating cables are especially useful in applications where temperatures vary, as they automatically adjust their output to match ambient conditions. This feature not only saves energy but also prevents overheating. Heating cables can be installed in hazardous or explosive environments, provided they meet ATEX or IECEx standards. They are often paired with thermostats and sensors to ensure temperature accuracy and safety. In cold climates or outdoor installations, heating cables prevent freezing in pipes, ensuring uninterrupted operation. Their flexibility and ease of installation make them suitable for both small-scale and large industrial setups. When chosen correctly and installed properly, heating cables can operate for many years with minimal maintenance. They are essential for keeping industrial processes stable, efficient, and safe.

Insulation materials

Insulation materials play a crucial role in preserving the heat delivered by process heating systems. Without insulation, much of the energy generated by heating cables or other elements would be lost to the environment, reducing efficiency and increasing operating costs. Insulation helps maintain consistent temperatures within pipes, tanks, and vessels by minimizing heat transfer to surrounding air. Materials commonly used include fiberglass, mineral wool, aerogel, and polyurethane foam, each selected based on temperature range, moisture exposure, and mechanical durability. For outdoor or harsh environments, weather-resistant and moisture-sealed insulation is preferred to prevent degradation. In addition to thermal insulation, acoustic and fire-resistant materials may also be used depending on industry standards. Proper installation of insulation materials is just as important as the material itself—gaps or compression can lead to thermal bridges and reduce effectiveness. Insulated surfaces also improve safety by reducing the risk of burns upon accidental contact. Furthermore, insulation supports compliance with energy efficiency regulations in many countries. When matched appropriately with heating systems, high-quality insulation materials significantly enhance overall system performance.

Control and monitoring units

Control and monitoring units are the intelligence behind any process heating system. They regulate the operation of heating cables or other elements based on real-time temperature data collected by sensors. These systems ensure that heat is applied precisely where it’s needed and at the exact temperature required. Advanced units include programmable logic controllers (PLCs), human-machine interfaces (HMIs), and SCADA systems for centralized control and remote access. This makes it possible to adjust settings, monitor performance, and receive alerts from virtually anywhere. Alarms can be configured to signal underheating, overheating, or system faults, allowing operators to act quickly. Many controllers now support data logging for performance analysis and regulatory compliance. Integration with IoT platforms enables predictive maintenance and helps reduce downtime. In sensitive industries like pharmaceuticals or energy, regulatory bodies may require detailed records of heating performance—something modern controllers can easily provide. Control units can be simple thermostats for small systems or complex multi-zone systems for large-scale industrial applications. Without a reliable control and monitoring setup, even the most advanced heating elements would be ineffective.

Advantages of Process Heating Systems

Process heating systems offer a wide range of advantages that go beyond simply raising temperatures—they are designed to improve production efficiency, product quality, and operational safety. One of the primary benefits is precise temperature control, which is essential in many industries where even slight variations can compromise product integrity. Automated control units and integrated sensors allow for real-time monitoring and adjustment, ensuring consistent heat delivery across all stages of a process. This level of control reduces the risk of human error and enhances repeatability in production. Additionally, energy efficiency is a major advantage; modern systems are designed to minimize heat loss and only deliver the amount of energy needed at a given time. This not only reduces operational costs but also supports environmental sustainability goals. In temperature-sensitive applications—such as chemical processing, food production, and pharmaceuticals—stable thermal conditions directly impact product quality, shelf life, and safety. These systems are also scalable, allowing businesses to expand or reconfigure them as production demands evolve. Furthermore, their modular nature simplifies maintenance and reduces downtime.

Another significant advantage of process heating systems is their adaptability to complex industrial environments. With customizable components and flexible design, these systems can be tailored to meet the specific requirements of nearly any industry, from oil refineries to cleanroom labs. In hazardous or explosive environments, specialized systems with certifications such as ATEX or IECEx ensure safety and compliance. Control systems can be connected to plant-wide networks, offering centralized access and data collection for quality control, audits, and performance evaluation. Many modern solutions include predictive maintenance features, allowing for early fault detection and reduced equipment failure. This proactive approach not only improves system longevity but also prevents unexpected shutdowns, which can be costly. Additionally, process heating systems can often be retrofitted into existing infrastructure, eliminating the need for extensive facility upgrades. Their design also supports a cleaner, quieter operation compared to combustion-based heating, making them more suitable for controlled or indoor environments. With all these advantages combined, process heating systems offer a long-term return on investment that benefits both production and sustainability.

Process Heating Solutions with Ignis Trace

Ignis Trace delivers advanced engineering and custom-built technologies to support industrial operations with efficient and intelligent heating solutions. With years of experience across multiple sectors, Ignis Trace designs each process heating system to fit the specific needs of its client—whether the application involves high-temperature chemical reactions, sensitive food production, or pharmaceutical-grade sterilization. Every project begins with a detailed analysis of the production environment, heat requirements, safety regulations, and operational goals. Based on this information, the team designs a tailored system that integrates heating cables, insulation materials, and smart control units into a unified solution. These systems are not off-the-shelf—they’re engineered for long-term efficiency, scalability, and safety. From small-scale applications to complex industrial networks, Ignis Trace provides end-to-end services including design, installation, commissioning, and support. One of the key advantages is the firm’s ability to integrate IoT-based monitoring tools, offering real-time insights, alarms, and energy tracking through user-friendly dashboards. Whether your operation is fully automated or manually controlled, Ignis Trace ensures full compatibility and seamless integration.

The company's commitment to quality, innovation, and safety is reflected in its compliance with international standards and certifications. Ignis Trace understands the high stakes involved in industrial heating—whether it's keeping pipelines from freezing, maintaining process fluid temperatures, or preventing material degradation due to heat loss. For this reason, each component is carefully selected and tested to perform reliably under real-world conditions. In addition to system reliability, Ignis Trace also emphasizes sustainability, offering energy-efficient solutions that align with corporate ESG goals and reduce carbon footprints. The team works closely with plant engineers and operations managers to ensure every solution not only meets technical specifications but also supports broader business objectives like cost savings, process optimization, and safety improvement. Even after commissioning, Ignis Trace provides ongoing technical support, system monitoring, and optimization services. This customer-focused approach has earned them a strong reputation as a long-term partner in heating system integration. Whether you’re launching a new facility or modernizing an existing one, Ignis Trace provides the expertise and innovation needed to future-proof your operations.

Industry-specific Process Heating solutions

Ignis Trace recognizes that no two industries have identical heating requirements, which is why their process heating solutions are customized for each sector. In the chemical and petrochemical industries, for example, the company provides explosion-proof systems certified for hazardous zones, ensuring compliance with ATEX and IECEx standards. In the food and beverage sector, Ignis Trace designs hygienic heating systems made of stainless steel and compliant with food safety regulations. Pharmaceutical clients benefit from high-precision, cleanroom-compatible systems that meet GMP requirements and ensure consistent product quality. For the energy and utilities sector, Ignis Trace offers large-scale heat trace systems capable of operating in extreme weather conditions. Each solution is engineered to address specific challenges, such as heat loss prevention, temperature uniformity, or process stability. The company also supports facility retrofits by designing systems that integrate into existing infrastructure without disrupting production. Their engineers consider not only the heating technology but also control integration, energy optimization, and lifecycle management. This tailored approach helps reduce downtime, boost efficiency, and maintain compliance across industries. With Ignis Trace, clients receive more than equipment—they gain a full-service heating partner focused on results.

Areas of Application for Process Heating Systems

Industrial process heating systems are integral to a wide range of sectors where temperature control is essential for safety, efficiency, and quality assurance. These systems are used in both production and maintenance operations, serving roles that vary from preventing freezing in pipelines to enabling precise chemical reactions. Applications range from small-scale laboratories to sprawling energy facilities, with system configurations tailored to the requirements of each environment. For example, in the chemical sector, maintaining stable process fluid temperatures is vital for reaction accuracy and worker safety. In the food and beverage industry, hygiene and consistency are key, requiring heating systems that support both sanitation and temperature stability. Similarly, pharmaceutical manufacturing demands ultra-precise heat control to comply with strict regulatory standards. In power generation and oil refineries, heating is used to keep fluids at optimal viscosity, preventing clogging and system damage.

Process heating systems are highly adaptable and can be installed in both new facilities and retrofitted into existing infrastructure. This flexibility makes them ideal for industries undergoing modernization or those operating in harsh or variable climates. Heating cables, control units, and insulation materials can be customized to fit unique layouts and operating conditions. Moreover, these systems are increasingly integrated into digital management platforms, allowing operators to remotely monitor performance and receive alerts in real-time. Their use significantly reduces energy waste, operational downtime, and manual intervention. Industries that prioritize sustainability benefit from heating solutions that are both energy-efficient and capable of supporting renewable energy integration. As global industries continue to prioritize efficiency, traceability, and compliance, process heating applications will continue to expand into new sectors. Let’s now look more closely at how these systems are applied across four major industries.

Process Heating Applications in the Chemical and Petrochemical Industry

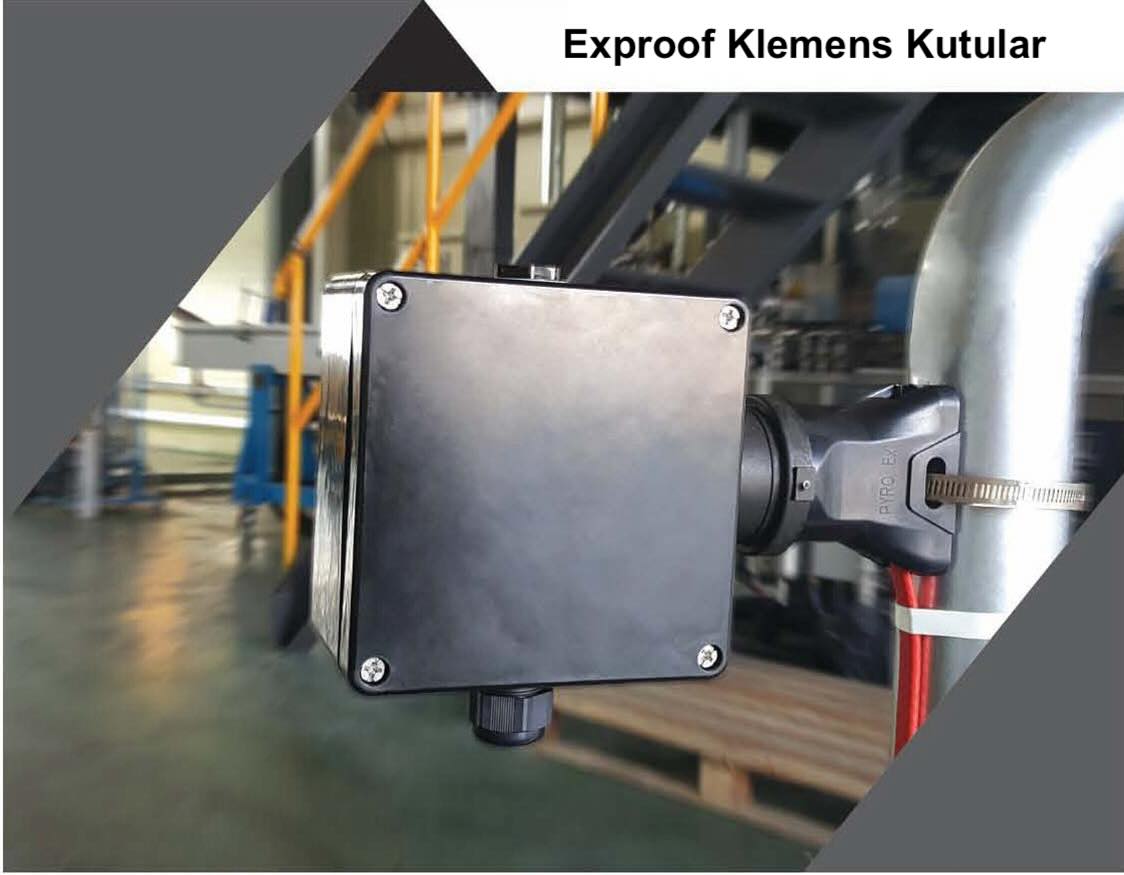

In the chemical and petrochemical sectors, process heating systems are essential for maintaining safety and process integrity. Many chemicals require precise temperatures to react correctly, and deviations can result in dangerous byproducts or production halts. Heating systems are used to keep fluids at specific viscosities, prevent crystallization, and enable phase changes. Reboilers, distillation columns, and storage tanks often rely on electric heat tracing or hot oil systems for consistent thermal management. In environments where explosive gases are present, explosion-proof components are mandatory, and Ignis Trace offers ATEX- and IECEx-certified systems designed specifically for hazardous zones. These systems also reduce the risk of pressure build-up or pipe rupture by preventing blockages caused by temperature fluctuations. With automated monitoring, operators can ensure that the heating system adjusts dynamically to process changes. The result is greater safety, lower energy costs, and improved throughput. Maintenance intervals are extended as well, thanks to the stability and reliability of modern heating components. In this high-stakes industry, reliable heat control is not optional—it’s fundamental to safe and efficient operations.

Process Heating Usage in the Food and Beverage Sector

In the food and beverage industry, process heating is used to ensure hygiene, consistency, and product quality. Applications include maintaining the flow of syrups, oils, chocolates, and dairy products, all of which can solidify or degrade without proper temperature control. Heat is also used in processes like pasteurization, sterilization, and CIP (Clean-In-Place) sanitation. Systems must comply with food-grade standards, meaning they’re often made from stainless steel and designed to be easy to clean. Ignis Trace offers heating solutions that are moisture-resistant and bacteria-proof, making them ideal for high-humidity environments like beverage bottling plants or dairy processing lines. In automated facilities, precise thermal control allows for real-time adjustments to meet recipe-specific temperature curves. This ensures that each batch meets the same high standards for taste, texture, and safety. Energy-efficient insulation and control systems help reduce costs while maintaining compliance with health and safety regulations. These systems not only protect the product but also enhance worker safety by reducing risks of burns and spills. The result is a clean, efficient, and tightly controlled production environment.

Process Heating Solutions in Energy, Refinery, and Facility Management

The energy and refinery sectors rely heavily on process heating systems to maintain productivity and operational stability. Pipelines transporting crude oil, natural gas, or other fluids must be kept above certain temperatures to avoid freezing or thickening, which could lead to costly system failures. Storage tanks, separators, and pumps also require heating elements to ensure uninterrupted operation during cold weather. Ignis Trace provides solutions that are robust enough for harsh environments, including offshore rigs and remote facilities. These systems often include advanced control panels with weather compensation and fault diagnostics to minimize human intervention. In facility management, process heating is used for HVAC systems, snow melting, and even floor heating in sensitive areas. Integrated with building management systems, heating components can be optimized for both comfort and efficiency. Predictive maintenance features help reduce energy waste and downtime, allowing operators to focus on core processes. With high ROI and reliable performance, process heating has become a key part of energy and facility infrastructure. Its adaptability makes it ideal for both centralized utilities and distributed energy systems.

Process Heating Systems in the Pharmaceutical and Healthcare Industry

In pharmaceutical manufacturing and healthcare environments, process heating systems are critical to product stability, compliance, and sterilization. These sectors demand ultra-precise thermal control, especially for processes like fermentation, drying, and liquid compounding. Heating is also vital in maintaining consistent temperatures for active pharmaceutical ingredients (APIs), which can degrade quickly if exposed to fluctuations. Cleanroom-compatible components made from non-contaminating materials are used to meet stringent Good Manufacturing Practice (GMP) guidelines. Ignis Trace designs systems with fine temperature accuracy and validation capabilities to meet regulatory audit requirements. These include data logging, alarm management, and system redundancy for mission-critical applications. In healthcare facilities, process heating is also used for sterilizing surgical instruments, warming fluids, and supporting HVAC systems. Safety is paramount, so all systems are built with multiple fail-safes and monitored continuously. With energy costs on the rise, healthcare institutions also benefit from the energy efficiency offered by modern heating systems. Whether in pharmaceutical labs or hospitals, precise heat control is crucial for ensuring both product efficacy and patient safety.

Türkçe

Türkçe