Cable insulation is the process of covering electrical conductors with protective materials to ensure the safe and efficient transmission of electricity. This insulation not only enhances electrical safety but also increases mechanical durability, reduces fire risk, and protects cables from environmental damage. Today, in industrial plants, infrastructure, and energy systems, cable insulation is a fundamental engineering requirement that ensures uninterrupted operation.

Proper insulation prevents energy losses and potential hazards, contributing to the longevity of the entire electrical system. Especially in high-voltage environments, electrical cable insulation plays a vital role in protecting both equipment and human life. A professionally applied insulation system not only boosts safety but also reduces maintenance and operational costs over time.

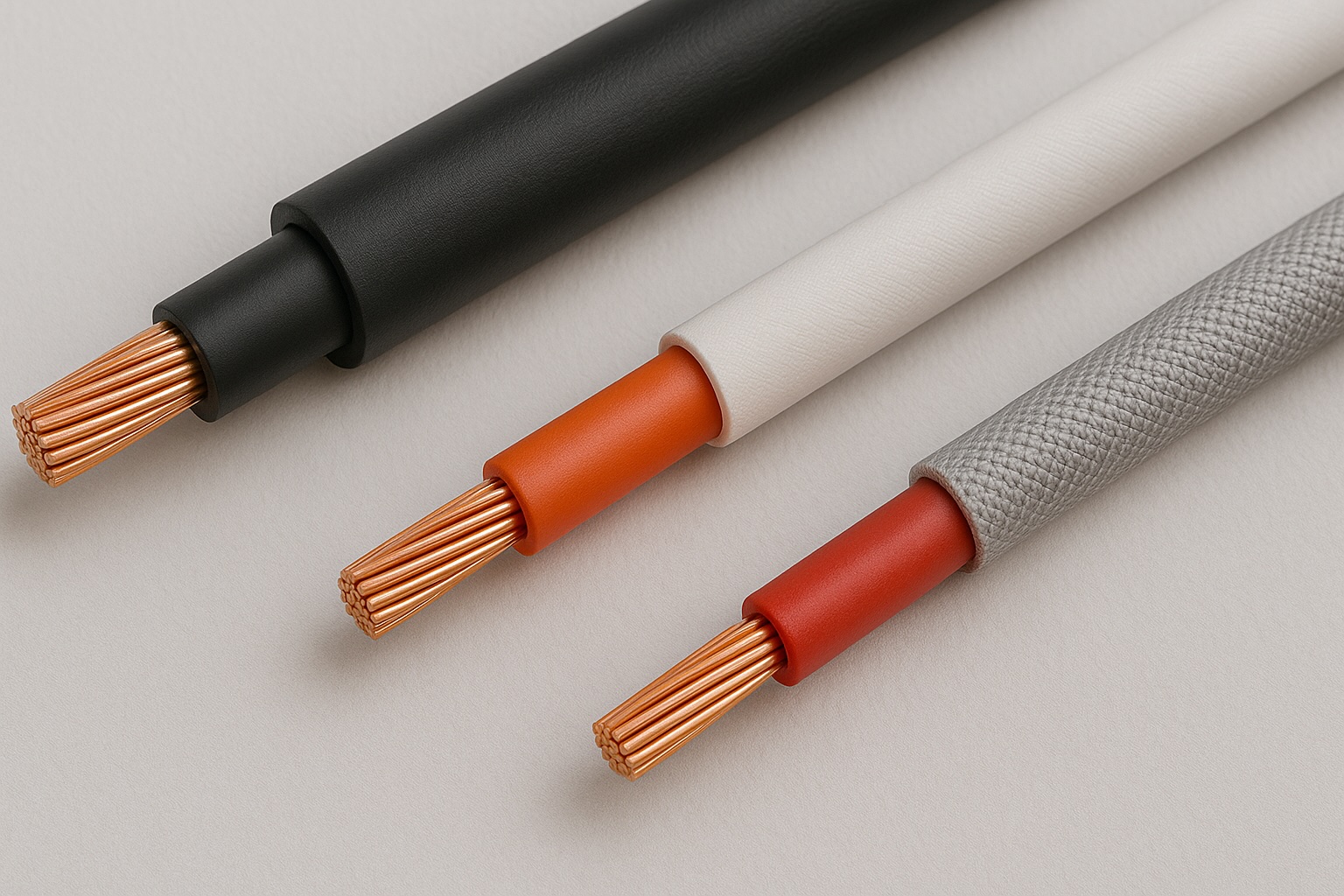

Insulation materials must be resistant to heat, moisture, chemicals, and physical stress. Depending on the application, materials such as PVC, rubber, silicone, Teflon, and neoprene are commonly used. Additionally, specific systems require precise solutions like cable connection insulation and cable transition insulation, particularly at joints and passage points. Selecting the right method and material ensures long-term performance and safety in all types of installations.

What is Cable Insulation?

Cable insulation is a protective process that involves covering electrical conductors to prevent the unwanted flow of electricity and safeguard the system from external factors. It ensures that electric current flows through the intended path while protecting people and surrounding equipment from electric shocks, short circuits, and fire hazards. The primary goal of insulation is to ensure system safety and long-term reliability in both residential and industrial electrical installations.

Electrical cable insulation is also vital for system efficiency and energy conservation. When cables are not properly insulated, moisture, temperature fluctuations, chemicals, or mechanical impact can significantly reduce the cable’s performance and lifespan. Therefore, using suitable materials and applying them correctly is essential. High-quality insulation prevents energy loss, increases operational efficiency, and lowers maintenance costs. As such, cable insulation plays a critical role in everything from household wiring to large-scale industrial power networks.

How is Cable Insulation Done?

The process of applying cable insulation begins with selecting the right insulation material based on the cable type and the environmental conditions it will be exposed to. Factors such as temperature, humidity, chemical exposure, and mechanical stress all influence material choice. Once the appropriate material is chosen, the insulation is typically applied using an extrusion method, where the material is heated, melted, and evenly coated around the conductive core of the cable.

In addition to full-length insulation, specialized techniques are used for cable connection insulation, particularly at joints, splices, and termination points. These areas are more vulnerable to external factors and require targeted protection using methods like heat-shrink tubing, resin kits, or molded parts. Similarly, cable transition insulation is applied in areas where cables pass through walls, panels, or equipment to prevent mechanical damage and environmental exposure. After application, insulation is tested to verify electrical resistance and ensure it meets safety standards. Proper application by skilled professionals ensures both performance and long-term safety.

What Are the Benefits of Cable Insulation?

Cable insulation offers multiple advantages, primarily in terms of electrical safety and system performance. The most important benefit is its ability to prevent current leakage, short circuits, and electrical shocks by keeping the current within the conductor. This not only protects users but also safeguards electrical equipment. High-quality insulation also acts as a barrier against moisture, dust, chemicals, and physical impact, ensuring the durability and reliability of the cable in challenging environments.

Cable insulation also plays a key role in reducing energy loss and extending the service life of cables. In industrial facilities where uptime is critical, proper insulation minimizes failures and ensures operational continuity. It also contributes to fire safety by limiting the risk of ignition due to electrical faults. Furthermore, insulation can reduce electromagnetic interference, which is essential in sensitive areas like data centers, hospitals, and laboratories. In short, cable insulation is not just a protective layer—it’s a fundamental element of system efficiency and safety.

What Are Cable Insulation Materials?

The choice of cable insulation materials depends on the operating environment, the voltage level, and the durability required. Insulation materials must withstand heat, moisture, chemicals, and physical stress while ensuring reliable electrical performance. Flexibility, cost-effectiveness, and environmental resistance are also factors that guide the selection process.

The choice of cable insulation materials depends on the operating environment, the voltage level, and the durability required. Insulation materials must withstand heat, moisture, chemicals, and physical stress while ensuring reliable electrical performance. Flexibility, cost-effectiveness, and environmental resistance are also factors that guide the selection process.

Some of the most widely used insulation materials include PVC, silicone, rubber, Teflon, XLPE, and neoprene. Each material has unique properties that make it suitable for specific applications. Additionally, advanced solutions such as paper, FEP, and TPE are used in specialized industries. Understanding the advantages of each material helps engineers apply the most effective insulation method for each system.

PVC - Rubber - Silicone

PVC is cost-effective and widely available, making it ideal for standard applications. Rubber adds strength and flexibility, offering resistance to abrasion and impact. Silicone stands out for its exceptional heat resistance, maintaining reliable insulation even under extreme temperatures. Together, these three materials cover a wide range of everyday insulation needs in electrical installations.

PE - XLPE

PE (Polyethylene) is highly effective in providing moisture resistance, which makes it a strong choice for underground or outdoor cable installations. XLPE (Cross-Linked Polyethylene) offers superior thermal resistance and longer lifespan. Because of its durability, XLPE is often used in high-voltage power distribution and industrial systems where reliability is critical for safe and efficient operations.

Teflon (PTFE)

PTFE, commonly known as Teflon, is renowned for its resistance to chemicals and high temperatures. It is especially valuable in industries such as aerospace, defense, and laboratories, where cables are exposed to harsh environments. PTFE also supports high-frequency signal transmission, making it suitable for sensitive electronic systems that demand both reliability and excellent electrical performance.

TPE - Neoprene - Rubber

TPE provides flexibility and eco-friendly qualities, while neoprene is favored for its strong resistance to water and chemicals. Rubber remains a versatile option due to its toughness and electrical insulation capacity. This combination is often used in outdoor installations and heavy-duty environments where cables must endure mechanical stress and challenging weather conditions without losing efficiency.

Wireless Techniques (Paper - FEP - TPE)

Certain applications rely on alternative or wireless insulation methods. Paper insulation, though older, is still found in traditional and retro systems. FEP provides exceptional high-performance insulation, particularly for specialized electronic equipment. TPE is increasingly used as a modern and environmentally conscious alternative. These materials offer engineers flexibility in meeting specific insulation requirements.

How is Cable Insulation Applied?

The application of cable insulation depends on the type of cable, the installation environment, and the required voltage level. The process usually starts by preparing the conductor surface to ensure it is clean and ready for insulation. The selected insulation material is then applied, most often through an extrusion process. In this method, the insulation material is heated until it melts and is then evenly coated around the conductor, forming a strong protective layer. This ensures both electrical safety and mechanical durability.

In specific cases, localized techniques such as cable transition insulation may be required where cables pass through walls or enclosures. Similarly, cable connection insulation is applied at joints and splicing points to provide extra safety against environmental exposure and electrical faults. After insulation is completed, testing is carried out to measure electrical resistance and verify compliance with safety standards. Professional application by trained experts is essential, as it guarantees both system reliability and long-term protection.

Professional Cable Insulation Solutions with Ignis Trace

Ignis Trace specializes in advanced industrial insulation solutions, offering reliable and customized services in the field of cable insulation. Every project is evaluated based on its operational environment, and the most suitable insulation materials and methods are carefully selected. From design to implementation, Ignis Trace applies international standards, ensuring the highest level of safety, efficiency, and durability in all insulation systems. The company’s experienced team provides end-to-end solutions that meet both technical and regulatory requirements.

In harsh conditions such as extreme heat, chemical exposure, or outdoor environments, Ignis Trace’s tailored methods deliver long-lasting protection. The company’s expertise extends across cable connection insulation, cable transition insulation, and comprehensive electrical systems, ensuring maximum safety and reliability. With a professional engineering approach and a commitment to sustainability, Ignis Trace guarantees that each insulation solution enhances system performance while reducing long-term operational costs.

Where Is Cable Insulation Used?

Cable insulation is used in a wide range of environments, from everyday residential installations to large-scale industrial projects. In homes and commercial buildings, it ensures the safe operation of electrical wiring by preventing short circuits and accidental contact. In power distribution networks, insulation is essential for protecting cables against weather conditions, moisture, and mechanical impact. Energy plants and underground systems also rely on high-quality insulation to maintain uninterrupted power flow and system reliability.

In industrial facilities such as chemical plants, refineries, and mining operations, cables are exposed to extreme heat, vibrations, and chemical vapors. In these areas, specially designed insulation materials provide the necessary durability. Data centers, hospitals, and laboratories also benefit from insulation by reducing electromagnetic interference that could disrupt sensitive equipment. Additionally, industries like automotive, aerospace, and defense depend on specialized insulation to guarantee safety and high performance in demanding conditions.

What Are Common Problems in Cable Insulation?

One of the most common problems in cable insulation is the use of unsuitable materials that do not match the environmental or operational requirements. When insulation is not designed to handle heat, moisture, or chemical exposure, it deteriorates quickly and loses its protective function. Installation errors, such as uneven application or insufficient coverage, can also lead to energy leakage, overheating, and reduced cable lifespan. These issues compromise both system efficiency and safety.

Another frequent issue is inadequate protection in outdoor or high-risk environments. UV exposure, mechanical stress, and water ingress can weaken insulation layers if not properly designed. Weak points often occur at joints and splices, where poor cable connection insulation can allow moisture penetration and cause electrical arcs. Such failures not only lead to costly downtime but also increase fire risks. Regular inspections, proper material selection, and professional installation are critical for preventing these common insulation problems.

Standards and Safety Rules Related to Cable Insulation

Cable insulation is governed by international standards and safety regulations to ensure reliable and secure electrical systems. These standards define the required properties of insulation materials, such as resistance to heat, fire, and mechanical stress. They also outline testing procedures to verify the electrical resistance and durability of insulated cables. Compliance with these rules is crucial for both safety and regulatory approval in industrial and residential installations.

Particularly in hazardous environments, special certifications are mandatory. For example, explosion-proof (Exproof) requirements apply in areas with flammable gases or dust, while fire safety standards are essential in buildings and public facilities. Professional companies must follow these guidelines to minimize risks, extend system lifespan, and protect human life. Below are two of the most critical safety areas in cable insulation.

Safety Standards for Exproof (Explosion-Proof) Insulation

In environments containing flammable gases, vapors, or dust, cables must meet Exproof standards to prevent ignition. Electrical cable insulation in these areas must be non-sparking, flame-retardant, and capable of withstanding harsh conditions. Standards such as IEC 60079 provide detailed requirements for ensuring safety in explosive atmospheres. Proper implementation prevents catastrophic accidents in high-risk industries like oil, gas, and mining.

Fire Safety Standards

Fire-resistant cable insulation is designed to maintain functionality during extreme heat or fire. Materials must comply with international standards such as IEC 60332 and EN 50575, which ensure cables resist flame spread and do not emit toxic gases. These requirements are vital in public spaces, hospitals, and critical facilities where safety and continuous operation are essential. Fire-safe insulation significantly reduces the risk of damage and protects lives.

Türkçe

Türkçe