In high-risk industrial environments, safety is not just a regulatory requirement but a critical operational priority. The SIL certificate is an internationally recognized safety rating that measures the reliability and risk reduction performance of safety instrumented systems. SIL, which stands for Safety Integrity Level, defines how effectively a system can perform its required safety function under specified conditions. It provides a structured and measurable approach to reducing risks associated with hazardous industrial processes.

What Is the SIL Certificate?

The SIL certificate is an official verification that a safety instrumented system or component meets a defined Safety Integrity Level according to international standards. It confirms that the system has been designed, tested, and validated to perform a specific safety function with a measurable and acceptable probability of failure. Rather than being a simple product approval, the certification reflects a comprehensive evaluation process covering system architecture, hardware reliability, software development practices, and lifecycle management. The main objective is to ensure that safety functions will operate correctly when required, especially in hazardous industrial conditions.

The Main Purpose and Importance of the SIL Certificate

The main purpose of the SIL certificate is to ensure that safety instrumented systems reduce industrial risks to an acceptable and measurable level. In high-hazard environments, even a single system failure can lead to severe consequences, including injuries, environmental damage, or significant financial loss. The SIL framework provides a structured methodology to identify hazards, assess risks, and define the required level of risk reduction. By assigning a specific Safety Integrity Level, organizations can clearly determine how reliable a safety function must be. This prevents both under-protection and unnecessary overdesign.

SIL Levels and the Differences Between Them

SIL levels define the degree of risk reduction provided by a safety function and are categorized into four distinct levels: SIL 1, SIL 2, SIL 3, and SIL 4. Each level corresponds to a specific range of probability of dangerous failure and a defined risk reduction factor. As the SIL level increases, the required reliability of the safety function becomes significantly higher. The selection of the appropriate level is based on detailed risk analysis, considering potential hazards, severity of consequences, and likelihood of occurrence. This structured classification ensures that safety systems are designed proportionally to the actual level of risk present in the industrial process.

SIL 1: Low Risk Level

SIL 1 represents the lowest level of safety integrity within the SIL framework and is typically applied to systems where the risk level is considered relatively low. At this level, the safety function is required to reduce risk to an acceptable threshold, but the probability of dangerous failure is higher compared to upper SIL levels. SIL 1 is commonly used in applications where the potential consequences of failure are limited and unlikely to result in severe injury, major environmental damage, or catastrophic financial loss. Even though it is the lowest classification, it still requires structured risk assessment and documented verification processes.

SIL 2: Medium Risk Level

SIL 2 is assigned to safety functions that address medium-level risks where potential failures could lead to serious injuries, significant environmental impact, or substantial financial losses. Compared to SIL 1, this level requires a considerably lower probability of dangerous failure and a higher risk reduction factor. SIL 2 is widely implemented in industries such as chemical processing, power generation, and oil and gas operations, where safety systems must respond reliably under demanding operational conditions. The determination of SIL 2 is based on systematic hazard and risk assessments that evaluate severity, exposure frequency, and likelihood of failure.

SIL 3: High Risk and Complexity

SIL 3 is designated for safety functions that address high-risk industrial scenarios where failure could result in severe injuries, major environmental damage, or significant economic consequences. At this level, the acceptable probability of dangerous failure is extremely low, and the required risk reduction factor is substantially higher than in SIL 1 or SIL 2. SIL 3 is commonly required in sectors such as oil and gas, petrochemicals, large-scale power generation, and other critical process industries. The selection of SIL 3 typically follows detailed hazard and operability studies (HAZOP) and quantitative risk assessments.

SIL 4: Critical and Very High Risk Level

SIL 4 represents the highest level of safety integrity and is reserved for extremely critical applications where system failure could lead to catastrophic consequences. At this level, the probability of dangerous failure must be exceptionally low, and the required risk reduction factor is the highest within the SIL framework. SIL 4 is rarely implemented in conventional industrial facilities but may be required in sectors such as nuclear power, certain aerospace applications, or highly specialized high-hazard environments. The decision to apply SIL 4 is based on comprehensive quantitative risk assessments and strict regulatory expectations.

Required Standards for SIL Certification (IEC 61508 and IEC 61511)

The SIL certificate is based on internationally recognized functional safety standards, primarily IEC 61508 and IEC 61511. IEC 61508 is the foundational standard that defines the general requirements for electrical, electronic, and programmable electronic safety-related systems. It establishes the functional safety lifecycle, covering hazard analysis, risk assessment, system design, implementation, validation, operation, and maintenance. This standard provides the framework for determining Safety Integrity Levels and specifies both hardware and software requirements. Manufacturers and system integrators rely on IEC 61508 to develop products and systems that meet defined reliability targets.

SIL Calculation Methods and Parameters

SIL calculation methods are essential for determining whether a safety function meets the required reliability targets defined for a specific Safety Integrity Level. These calculations are based on quantitative risk assessment and statistical analysis of system performance. Engineers evaluate factors such as failure rates of components, diagnostic coverage, proof test intervals, and system architecture. The objective is to determine the Probability of Dangerous Failure and confirm that the achieved value falls within the acceptable range for the target SIL level. This analytical approach ensures that safety integrity is measurable rather than based on assumptions.

PFD (Probability of Failure) and RRF (Risk Reduction Factor)

PFD, or Probability of Failure on Demand, is a key metric used to evaluate how likely a safety function is to fail when it is needed. It is most commonly applied to demand-mode safety systems, such as emergency shutdown functions that operate only when a hazardous condition occurs. A lower PFD value indicates a more reliable safety function and stronger protection against dangerous events. SIL levels are directly linked to defined PFD ranges, which makes PFD one of the most important parameters in functional safety verification. Component failure rates, diagnostic effectiveness, proof test intervals, and system architecture all influence the final PFD calculation.

Hardware Fault Tolerance (HFT)

Hardware Fault Tolerance (HFT) refers to the ability of a safety system to continue performing its required safety function even when one or more hardware components fail. It is a critical architectural parameter in achieving and maintaining a specific Safety Integrity Level. HFT defines how many faults can occur before the safety function is lost. For higher SIL levels, increased hardware fault tolerance is typically required to ensure that no single failure can compromise system integrity. This is commonly achieved through redundant system configurations such as 1oo2 (one out of two) or 2oo3 (two out of three) architectures.

How Does the SIL Certification Process Work?

The process of obtaining a SIL certificate follows a structured functional safety lifecycle defined by international standards. It begins with hazard identification and risk assessment, where potential dangerous events are analyzed to determine the required Safety Integrity Level. Based on this evaluation, a Safety Requirements Specification (SRS) is developed, clearly defining the performance and reliability targets of the safety function. System architecture is then designed to meet the selected SIL, incorporating appropriate redundancy, diagnostic coverage, and hardware fault tolerance. Throughout this stage, failure rate data and risk reduction calculations are carefully documented.

Advantages of Having a SIL Certificate

Having a SIL certificate provides organizations with measurable assurance that their safety systems meet internationally recognized functional safety standards. One of the primary advantages is enhanced risk management, as certified systems are designed to reduce hazardous events to acceptable levels. This significantly lowers the likelihood of accidents, equipment damage, environmental harm, and production downtime. By implementing certified safety solutions, companies can improve operational continuity and protect both personnel and assets. Furthermore, compliance with SIL requirements demonstrates a proactive approach to safety engineering rather than a reactive response to incidents.

In Which Industries Is SIL Certification Mandatory?

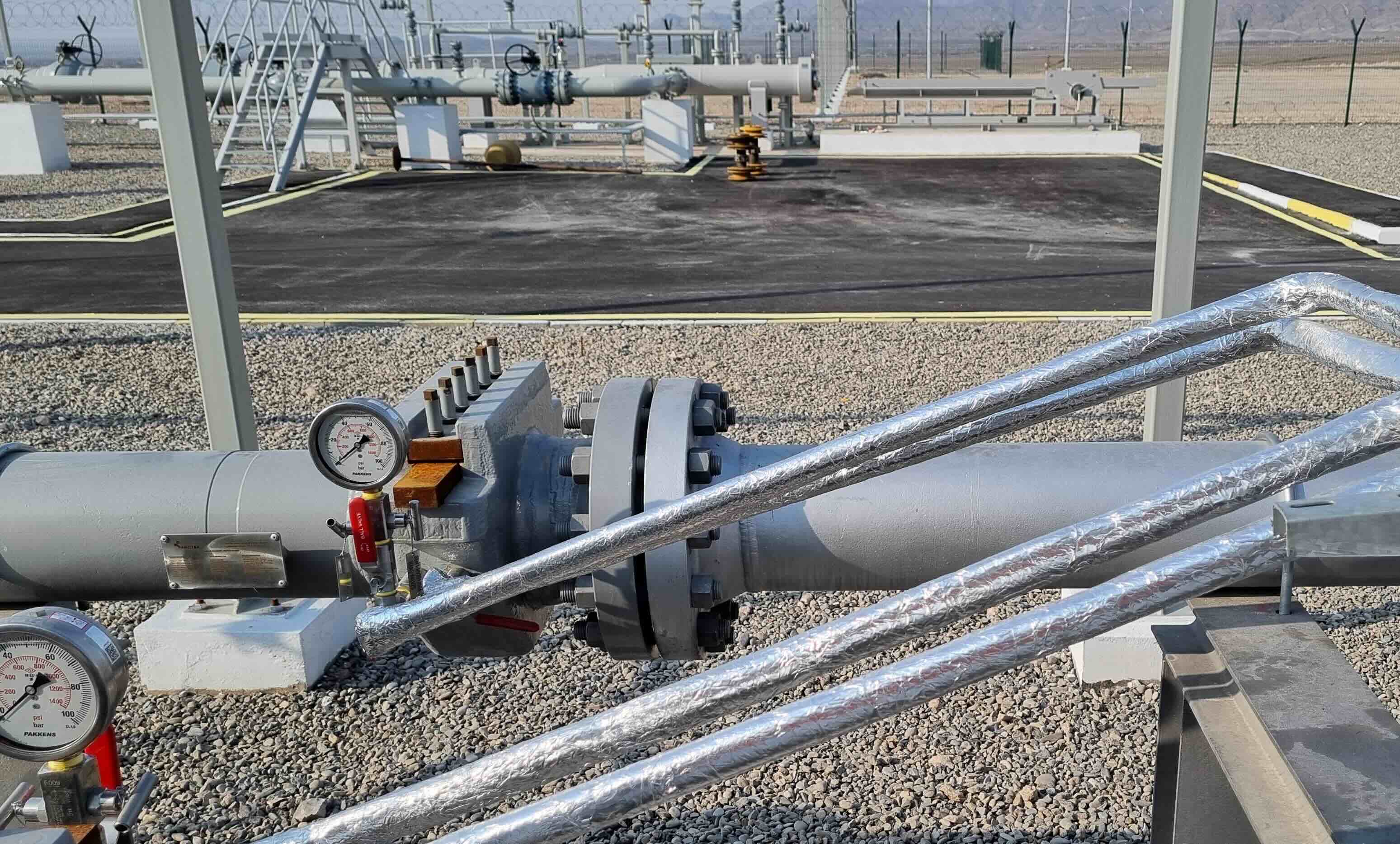

SIL certification is mandatory or strongly required in industries where system failures can lead to severe safety, environmental, or economic consequences. The oil and gas sector is one of the most prominent examples, as exploration, refining, and distribution processes involve flammable and explosive materials. Similarly, petrochemical and chemical industries rely heavily on certified safety instrumented systems to control hazardous reactions and prevent catastrophic incidents. Power generation facilities, including thermal and nuclear plants, also require high-integrity safety systems to ensure operational stability and public safety. In these sectors, regulatory frameworks and international project specifications frequently mandate compliance with defined SIL levels.

Türkçe

Türkçe