In industries where temperature control and freeze protection are critical, selecting the right heat tracing cable is essential for maintaining efficient operations. Among the widely recognized solutions are the FBL cable and BSX Thermon heating cable, both designed to ensure stable and reliable thermal management.

FBL cable, often compared to BSX, stands out for its adaptable features and self-regulating technology, making it a powerful alternative. In this article, we will explore what FBL means, its applications, and how it compares to BSX in terms of technical specifications and usage.

What is FBL Cable?

FBL cable is a self-regulating heat trace cable used to provide freeze protection and maintain process temperatures in industrial settings. It adjusts its heat output based on the surrounding temperature, preventing overheating and improving energy efficiency.

But what does FBL mean? The acronym FBL typically refers to a type of cable designed for heat tracing applications, meaning it can control the temperature of pipes, tanks, and other equipment. With its self-regulating feature, FBL cable offers a dynamic solution for industries where maintaining stable temperatures is critical, especially in hazardous or harsh environments.

What are the Technical Specifications of FBL Cable?

The FBL cable comes with several technical specifications that make it suitable for various industrial applications. Below are the key technical details:

- Maximum maintain temperature (Power-on): 65°C (150°F)

- Maximum withstand temperature (Power-off): 85°C (185°F)

- Minimum installation temperature: -60°C

- Temperature classification (T-rating): T6 (85°C)

- Rated voltage: 100 ~ 120 Vac, 200 ~ 277 Vac

- Rated power output: 10, 16, 24, and 30 watt/m @ 10°C

- Nominal dimensions:

- FBL10x, 16x, 24x: 11.6 mm x 5.6 mm

- FBL30x: 13.6 mm x 5.6 mm

- Outer jacket materials:

- FR polyolefin: Suitable for exposure to aqueous inorganic chemicals

- Fluoropolymer: Designed for environments where exposure to organic chemicals or corrosives is expected

These features highlight the flexibility and durability of FBL cable, making it highly adaptable to different temperature maintenance needs in industrial environments.

In Which Areas Is FBL Cable Used?

FBL cable is widely used across various industries for heat tracing applications due to its ability to regulate heat output and provide freeze protection. Some of the most common areas where it is applied include:

- Water pipelines: Used to prevent freezing and ensure continuous water flow in cold environments.

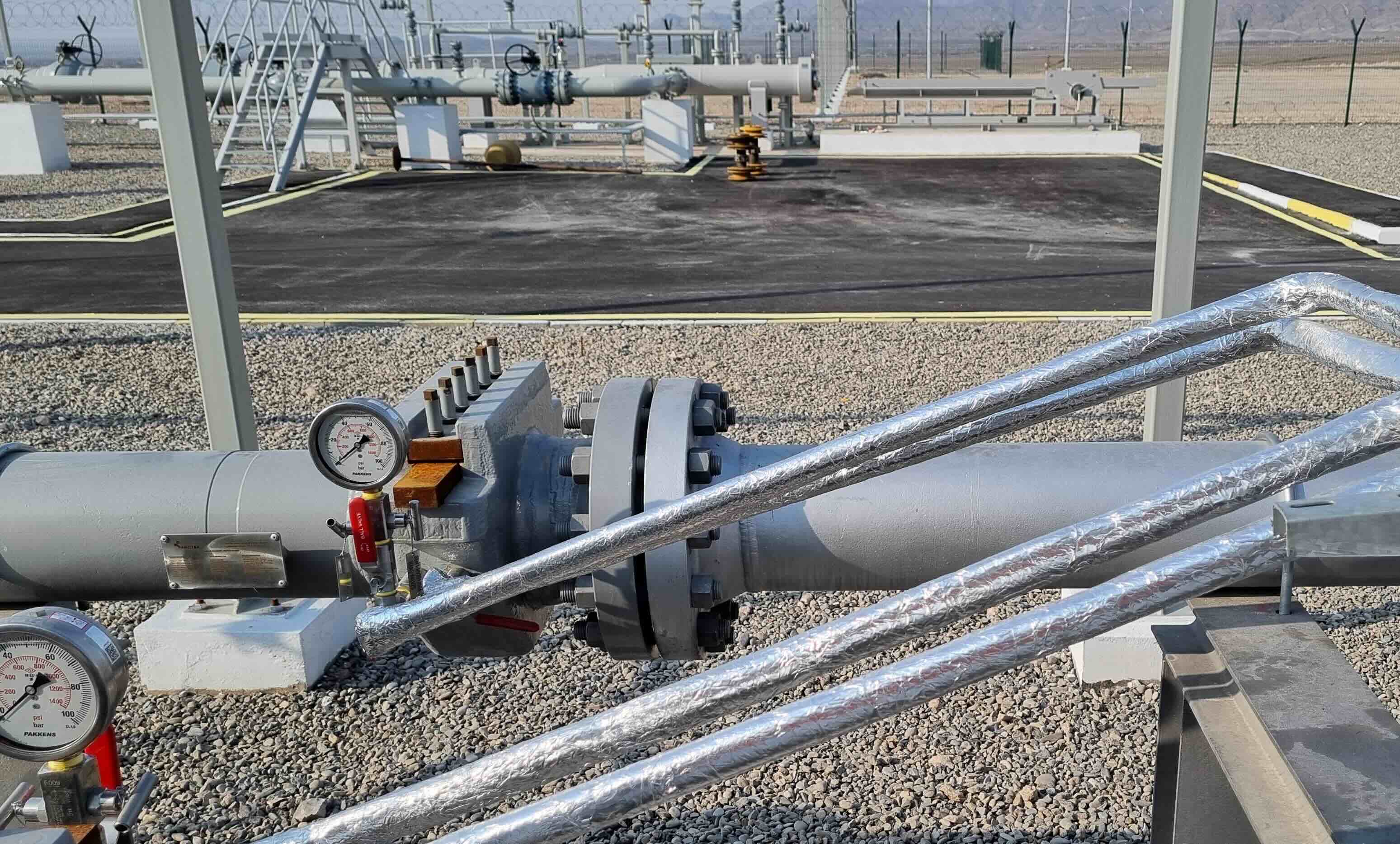

- Petrochemical plants: Provides temperature maintenance for pipelines in hazardous areas.

- Gas pipelines: Helps in maintaining consistent temperatures in gas transport systems.

- Chemical processing: Ensures the safe and efficient transport and storage of chemicals by stabilizing temperatures.

- Industrial tanks and equipment: Used to maintain operational temperatures in tanks and other equipment to ensure smooth industrial processes.

Thanks to its self-regulating nature, FBL cable is a versatile solution for industrial sectors requiring reliable temperature control and freeze protection.

What is BSX Thermon Heating Cable?

The BSX Thermon heating cable is a self-regulating heating solution designed for both freeze protection and process temperature maintenance in pipelines, tanks, and various equipment. Like the FBL cable, it adjusts its heat output automatically in response to changes in the surrounding temperature. This feature makes it highly energy-efficient, preventing unnecessary power usage and protecting systems from overheating or freezing.

BSX cable is approved for use in both non-hazardous (ordinary) and hazardous (classified) areas, making it a reliable choice for a variety of industries. By dynamically adjusting heat output, BSX cable ensures smooth, consistent temperature regulation across different environmental conditions.

What are the Technical Specifications of BSX Cable?

BSX Thermon heating cable comes with several key technical features that make it suitable for industrial applications requiring reliable temperature management. Some of the primary specifications include:

- Available watt densities: 10, 16, 26, and 33 W/m @ 10°C (3, 5, 8, 10 W/ft @ 50°F)

- Supply voltages: 110-120 Vac or 208-277 Vac

- Maximum maintenance temperature: 65°C (150°F)

- Maximum continuous exposure temperature (Power-off): 85°C (185°F)

- Minimum installation temperature: -51°C (-60°F)

- Minimum bend radius:

- @ -15°C (5°F): 10 mm (0.38”)

- @ -60°C (-76°F): 32 mm (1.25”)

- Temperature classification (T-rating):

- 10, 16, 26 W/m → T6 85°C (185°F)

- 33 W/m → T5 100°C (212°F)

These specifications ensure that BSX cable can be installed in a variety of environments and provide effective temperature control even under extreme conditions.

In Which Areas Is BSX Cable Used?

BSX cable is designed to serve a wide range of industrial applications, particularly in areas that require freeze protection or process temperature maintenance. Some of its primary uses include:

- Pipelines (metallic and non-metallic): Ideal for preventing pipes from freezing in cold temperatures, ensuring consistent flow and operation.

- Industrial tanks and equipment: Maintains necessary temperatures in tanks and other critical equipment for smooth industrial processes.

- Chemical and petrochemical facilities: Widely used in hazardous areas for temperature control to ensure safety and efficiency.

- Food and beverage industry: Helps maintain optimal temperatures during processing to ensure product quality.

With its ability to automatically adjust heat output, BSX cable is highly effective in industrial environments where temperature control is critical to operations.

What are the Similarities Between BSX Thermon and FBL Cable?

Both BSX Thermon and FBL cable are reliable, self-regulating heat trace cables designed to provide efficient freeze protection and temperature maintenance in industrial environments. Despite being different products, they share several key similarities that make them effective solutions for temperature control. These similarities include:

- Self-Regulating Technology: Both BSX and FBL cables are designed to automatically adjust their heat output in response to ambient temperature changes. This feature prevents overheating, improves energy efficiency, and ensures that both cables deliver only the necessary amount of heat to maintain optimal conditions.

- Versatile Application in Hazardous and Non-Hazardous Areas: Both cables are certified for use in hazardous (classified) and non-hazardous (ordinary) locations, making them suitable for a wide variety of industries, including petrochemical, chemical processing, and general industrial applications.

- High Temperature Resistance: BSX Thermon and FBL cables can both maintain a maximum operating temperature of 65°C (150°F) and withstand a continuous exposure temperature of 85°C (185°F) when powered off. This ensures their durability and reliability under demanding conditions.

- Energy Efficiency: Thanks to their self-regulating features, both cables minimize energy consumption by reducing heat output when less is required, helping to lower operating costs in energy-intensive environments.

- Flexible Installation: Both BSX and FBL cables can be cut to any length to suit specific installation needs. Their ability to self-regulate and provide independent heat output along the entire length makes them adaptable to various setups in complex industrial environments.

In summary, BSX Thermon and FBL cables are both efficient, energy-saving solutions for industrial heat tracing. Their similarities in functionality, safety certifications, and flexibility make them excellent choices for industries that need reliable temperature management systems.

Türkçe

Türkçe