In modern industries, industrial heat control and industrial insulation systems are critical to ensuring safe, efficient, and cost-effective production processes. These systems are designed to regulate temperatures, reduce energy losses, and extend the service life of equipment. Proper heat management is not only about controlling temperature; it is also about optimizing processes, minimizing operational risks, and achieving sustainability goals.

By integrating industrial heat monitoring systems, businesses can continuously track processes and identify potential failures before they escalate into major issues. This proactive approach reduces downtime and increases reliability. Moreover, energy-efficient industrial heating solutions help industries cut costs while maintaining productivity. From chemical plants to energy facilities, these systems are essential for maintaining safety, quality, and operational efficiency.

The Importance of Industrial Heat Control Systems

Heat control systems in industrial facilities play a vital role in achieving production efficiency and safety. Without proper regulation, temperature fluctuations can cause significant equipment damage, product defects, or even safety hazards. Industrial heat control systems minimize these risks by ensuring consistent operating conditions. They also help facilities meet strict quality standards while lowering operational costs.

Another critical aspect of these systems is safety. Especially in facilities handling flammable or hazardous substances, controlling heat prevents accidents and ensures compliance with international safety standards. Additionally, energy-efficient industrial heating solutions help companies align with sustainability targets by reducing emissions and optimizing resource usage. As a result, investing in heat control technologies is no longer optional but a strategic necessity for all modern industries.

Main Heat Control and Insulation Systems Used in Industry

Different industries require customized industrial insulation and heat control solutions to match their processes and environmental conditions. Systems such as heating cables, ex-proof devices, control panels, and insulation jackets are tailored to maintain operational stability while minimizing energy losses. These solutions are applied across pipelines, storage tanks, pumps, and other process equipment.

Ignis Trace offers a broad portfolio designed to meet these diverse needs. With advanced industrial heat monitoring systems, companies can achieve real-time supervision, while high-performance heating and insulation products safeguard critical assets. Below are the main types of heat control and insulation systems widely used in industry.

Heating Cables

Heating cables are one of the most common industrial heating solutions. They are used to prevent freezing, maintain process temperatures, and ensure fluidity in pipelines and tanks. These cables are available in different power capacities and designs, offering both flexibility and durability. Their ease of installation and energy efficiency make them indispensable for industries such as chemicals, petrochemicals, and energy.

Ignis Trace provides specialized heating cables that meet demanding industrial standards. To explore more details, visit the Heating Cables page.

Ex-Proof Products

In hazardous environments, safety comes first. Ex-proof products are engineered to operate safely in explosive or flammable atmospheres, minimizing risks of ignition. These solutions comply with global safety certifications, ensuring both operational continuity and workforce protection.

Heat Control Panels

Heat control panels act as the central hub for managing heating systems. They integrate with sensors, heating cables, and monitoring devices to provide precise control and automation. With real-time data, operators can optimize performance, reduce energy consumption, and prevent failures.

Ignis Trace’s advanced panels are designed to work seamlessly with industrial heat monitoring systems, ensuring top-level safety and efficiency. More information can be found on the Heat Control Panels page.

Heated Industrial Insulation Jackets

Heated industrial insulation jackets are flexible, removable covers designed for pipes, valves, tanks, and pumps. They minimize heat loss while keeping process temperatures stable. Their removable design simplifies maintenance, significantly reducing downtime during inspections or repairs..

Fuel and Chemical Leak Detection Systems

Leak detection systems are vital in industries handling hazardous liquids. Fuel and chemical leak detection systems identify even the smallest leaks at an early stage, preventing environmental damage, production interruptions, and safety risks. These systems use sensitive sensors to activate alarms before a situation escalates.

Technologies Used in Industrial Heat Control Systems

The effectiveness of industrial heat control depends heavily on the technologies applied. Sensors, automation software, and real-time monitoring tools all contribute to achieving precision and reliability. These technologies not only ensure optimal temperatures but also reduce costs by preventing energy waste.

Ignis Trace incorporates the latest innovations in its product portfolio, combining industrial heat monitoring systems with heating and insulation equipment. This integrated approach allows industries to predict potential failures, schedule preventive maintenance, and operate sustainably. Below are two core technologies commonly used.

Heat Trace System

The Heat Trace system is one of the most widely adopted solutions in process industries. It uses electric heating cables to maintain or raise the temperature of pipelines, tanks, and other equipment. By operating only where and when heat is required, it ensures high energy efficiency.

Ignis Trace provides robust Heat Trace systems suitable for extreme climates and demanding industrial conditions. Learn more by visiting the Heat Trace System page.

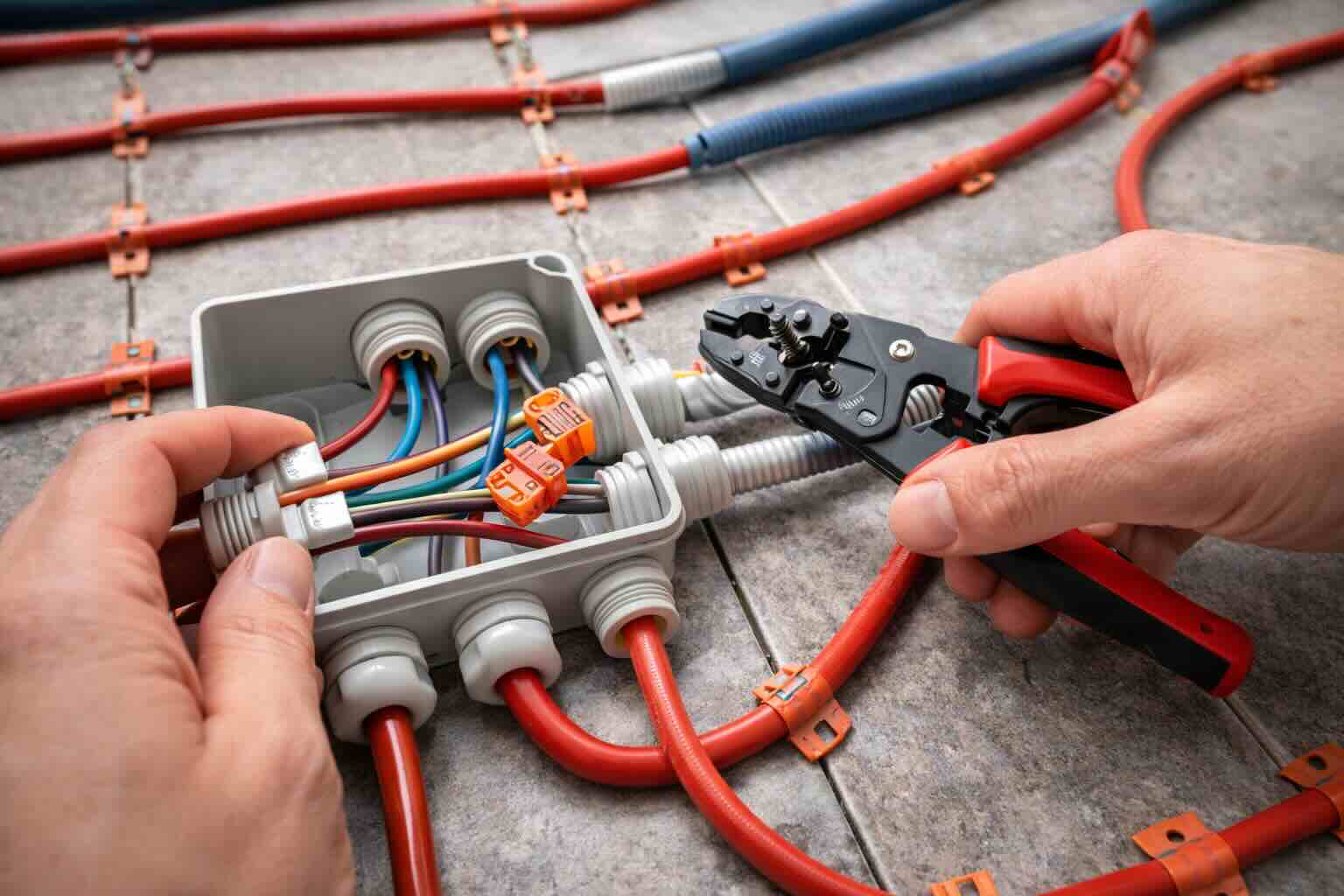

Cases, Mounting Hardware, and Connection Kits

Cases, mounting hardware, and connection kits ensure safe and reliable installation of heating equipment. These components are essential for maintaining system integrity, reducing failures, and optimizing energy performance.

Ignis Trace supplies high-quality, certified installation materials that integrate seamlessly with industrial insulation and heating systems. Further details can be found on the Cases, Mounting Hardware, and Connection Kits page.

Challenges and Solutions in Industrial Heat Control

One of the main challenges in industrial heat control is adapting systems to diverse climates and working conditions. Poor insulation or incorrect equipment selection can lead to high energy losses and costly downtime. Maintenance delays also reduce efficiency and increase risks in large-scale facilities.

Ignis Trace addresses these challenges through advanced monitoring, durable insulation, and energy-efficient industrial heating solutions. Continuous supervision with industrial heat monitoring systems allows operators to identify problems early, ensuring uninterrupted production and lower operational costs.

Advantages Provided by Industrial Heat Control Systems

Investing in reliable industrial heat control and insulation technologies brings multiple benefits. Energy efficiency is among the most significant, as well-designed industrial insulation prevents unnecessary heat loss. Stable process conditions also improve product quality and consistency.

Safety is another key advantage. Automated industrial heat monitoring systems help detect irregularities in real time, preventing equipment damage or accidents. At the same time, high-performance industrial heating solutions reduce maintenance costs and extend equipment lifespan, contributing to both profitability and sustainability.

Areas of Use for Heat Control and Insulation Systems in Different Sectors

Industrial heat control and insulation systems have diverse applications across industries. In the chemical and petrochemical sectors, they ensure safe storage and transport of volatile substances. In the energy industry, they maintain critical infrastructure like pipelines and turbines at the right temperature for optimal performance.

The food industry uses these systems to maintain hygiene and quality standards, while the pharmaceutical sector applies industrial heat monitoring systems to ensure process stability for sensitive formulations. Additionally, mining and heavy industries rely on industrial heating solutions to maintain productivity under extreme conditions.

What Should Be Considered When Choosing Heat Control and Insulation Systems?

Selecting the right industrial heat control and industrial insulation system requires a careful evaluation of operational conditions and needs. Different equipment such as tanks, pipelines, and valves may demand specific solutions. Choosing energy-efficient technologies reduces costs over time, while ensuring compliance with international safety standards is equally important.

In hazardous environments, ex-proof products are essential for safety. Integrating industrial heat monitoring systems also ensures continuous performance supervision. Ignis Trace supports businesses by offering tailored industrial heating solutions that are both safe and sustainable, enabling industries to make the right long-term investments.

Türkçe

Türkçe